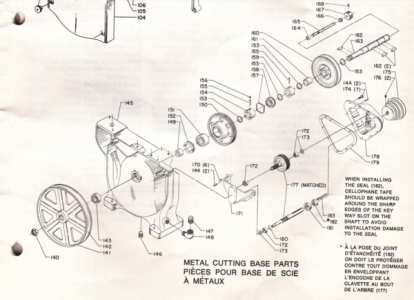

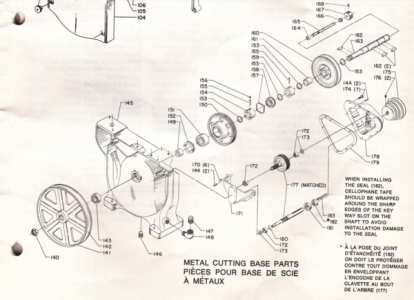

Thanks everyone for the advice, here's a diagram of the assembly from

the instruction guide on Vintage Machinery:

What makes sense to me is for nut (#140) to tighten the wheel (#141), the inner race of the bearing (#143), the spacer (#149), the inner race of the large gear wheel's bearing (#151) against the retaining ring (#153).

Since the big gear wheel rides on a bearing, I don't see why you'd need axial play there (but I'm willing to learn).

As-is, when nut (#140) is tightened, it'll pull the opposite side's bearing (#158) into the casting and crush it. Note that this casting is hollow, with fairly thin walls (1/8" maybe), which is different from the woodcutting model, where I believe the spindle goes through a bore solid through the casting.

I also don't think it makes sense for the big gear wheel (#150) to rub against the casting at one end of the axial play.

Note that there's a double clutch on the shaft to switch between direct drive for wood cutting through pulley (#160), to metal cutting through the gearbox and the big gear wheel (#150). When disengaged, the pulley will idle on a bushing (#161 - which I'll have to replace, oilite ordered), and when engaged, the gear wheel will idle on the bearing (#150).

EDIT: I was typing while you were posting your pics. It looks as though your spacer has a shoulder, or am I seeing it wrong? Is the spacer

located between the two bearings? It's not completely clear how the assembly goes together. But, again, if the spacer is simply located

between the bearings and rotates with the inner races on the shaft, the material probably isn't critical. Or, is there more going on here?

Yes, the spacer is steel, and it's located between two bearings. There's a shoulder on the shaft, as the IDs of the two bearings are different, and so there's a step in the spacer bore.

The big gear has helical teeth and such a gear will always place an axial thrust on the shaft it spins on. Are you absolutely certain that the cracked housing is because of the deformed or altered spacer you intend to make? Is it possible the axial forces are excessive for some reason? Are you certain this was assembled properly? Maybe something is in there backward...

Yeah, I don't know the history of this bandsaw, except that it's led a hard life. It was covered in chips-in-cutting-oil and sawdust when I got it, the bottom of the base was quite rusty, the big pulley was quite corroded and the keys in the step pulleys were out of place - one of them pushed all the way up the shallow of the keyway and nearly rubbing on the casting.

One thought I had was that the bearing was installed inside-out. This bearing has an inner race that's wider than the outer race, and offset to one side - by just about 65 thou.

I don't think this makes sense however, as the shielding on this bearing gives it an orientation for "outside", plus there'd have to be a spacer on the outside of the bearing to locate the wheel correctly...