I’m sure I’ll have many, many questions, but first and foremost is figuring out how much servo motor I will need.

Here is the open-source project I’m talking about:

www.youtube.com

www.youtube.com

James is driving the combination feed/leadscrew of his Grizzly G0602 benchtop lathe (10x22”, 1hp, 432 lb. shipping weight) using a Nema23 hybrid servo of 282 oz/in, about 2 N-m.

My lathe is 70s vintage, unknown maker, 12x36”, 3hp, about 1500 lb. Obviously I need a bigger servo, but I really have no idea how to go about calculating the torque I need. For now, my only idea has been to search for a CNC conversion kit for a similar lathe and see what they spec.

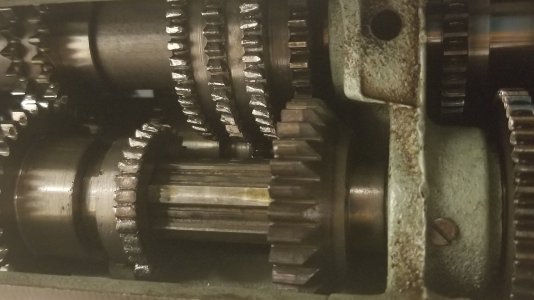

Picture below shows the condition of the QCGB and the reason I’m planning this conversion:

Here is the open-source project I’m talking about:

Lathe Electronic Leadscrew

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

James is driving the combination feed/leadscrew of his Grizzly G0602 benchtop lathe (10x22”, 1hp, 432 lb. shipping weight) using a Nema23 hybrid servo of 282 oz/in, about 2 N-m.

My lathe is 70s vintage, unknown maker, 12x36”, 3hp, about 1500 lb. Obviously I need a bigger servo, but I really have no idea how to go about calculating the torque I need. For now, my only idea has been to search for a CNC conversion kit for a similar lathe and see what they spec.

Picture below shows the condition of the QCGB and the reason I’m planning this conversion: