- Joined

- Jan 24, 2015

- Messages

- 239

I had a thought, which is always dangerous. My thought was that if I can get the shaft machined to within, say, 15 thou of the final dimension I could use a file to get the rest of the way.

Unfortunately, this material is quite resistant to filing! I have filed CI before, and this does not behave like I would expect (given my limited experience).

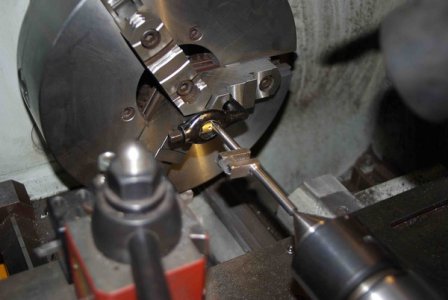

The photo below shows my attempt at smoothing the surface with a file. I used about 30 strokes of the file to get this.

The surface has not changed in appearance.

I then tried some medium grit 3M emory cloth. That did nothing to surface (no photo, sorry).

The set up is certainly stout enough to get something of a result from filing and/or abrasive cloth.

The lathe filing and sanding were done at around 300 rpm. The file was sharp, and the emory cloth was new.

Thank you for your help.

Cheers,

Tom

Unfortunately, this material is quite resistant to filing! I have filed CI before, and this does not behave like I would expect (given my limited experience).

The photo below shows my attempt at smoothing the surface with a file. I used about 30 strokes of the file to get this.

The surface has not changed in appearance.

I then tried some medium grit 3M emory cloth. That did nothing to surface (no photo, sorry).

The set up is certainly stout enough to get something of a result from filing and/or abrasive cloth.

The lathe filing and sanding were done at around 300 rpm. The file was sharp, and the emory cloth was new.

Thank you for your help.

Cheers,

Tom

Steve Shannon

Steve Shannon