- Joined

- Jan 24, 2015

- Messages

- 239

Dear All,

I am building the PMR #5 steam engine. It comes with a cast iron crankshaft. I am now trying to machine the crankshaft, and running into some chattering problems. He just keeps talking and talking about his difficulties with fairer sex. I feel like slapping him, but he obviously has not responded to that in the past.

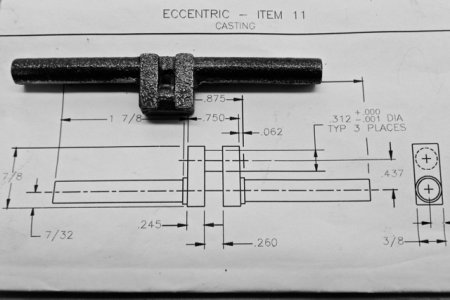

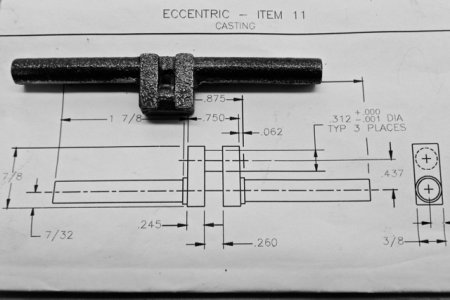

This the cast piece as I received it:

Also note the drawing.

I am trying to machine the main shaft. As I said above, I am getting a hell of a lot of chatter, chitter and whining. This is really annoying.

This is a photo of my setup. The steady rest was put in to try and the reduce chatter. It kinda helped.

This is a photo of the machined surface of the crankshaft. It's very ugly. It's ugly like that dame's ex, the one that shot me in that dark alley.

I have tried carbide insert tools and HSS tools ground for CI. The HSS tools were ground with 10-12 degree angles for side relief and front angle. The back rake was about 8 degrees. The front cutting edge angle varied from 80 to 60 degrees (the point as you look down on it).

I am spinning the piece between 200 - 450 rpm. Any faster and it starts to wobble like my drunk uncle that had ADHD.

All operations are being done on a Sherline 3.5" lathe.

So, my questions are:

1) What can I do to reduce chatter?

2) See question 1.

If your answer is "buy a bigger lathe" I will have to ask for your credit card number.

Seriously, what about trying different tool angles, or a different set up, or making a virginal sacrifice to Hephaestus? I'm assuming the sacrifice would involve virgin metal.

As I said, seriously, what can I do with the equipment I have to reduce chatter and make a nice looking crankshaft.

Thanks tons,

Tom, your humble beggar of advice.

I am building the PMR #5 steam engine. It comes with a cast iron crankshaft. I am now trying to machine the crankshaft, and running into some chattering problems. He just keeps talking and talking about his difficulties with fairer sex. I feel like slapping him, but he obviously has not responded to that in the past.

This the cast piece as I received it:

Also note the drawing.

I am trying to machine the main shaft. As I said above, I am getting a hell of a lot of chatter, chitter and whining. This is really annoying.

This is a photo of my setup. The steady rest was put in to try and the reduce chatter. It kinda helped.

This is a photo of the machined surface of the crankshaft. It's very ugly. It's ugly like that dame's ex, the one that shot me in that dark alley.

I have tried carbide insert tools and HSS tools ground for CI. The HSS tools were ground with 10-12 degree angles for side relief and front angle. The back rake was about 8 degrees. The front cutting edge angle varied from 80 to 60 degrees (the point as you look down on it).

I am spinning the piece between 200 - 450 rpm. Any faster and it starts to wobble like my drunk uncle that had ADHD.

All operations are being done on a Sherline 3.5" lathe.

So, my questions are:

1) What can I do to reduce chatter?

2) See question 1.

If your answer is "buy a bigger lathe" I will have to ask for your credit card number.

Seriously, what about trying different tool angles, or a different set up, or making a virginal sacrifice to Hephaestus? I'm assuming the sacrifice would involve virgin metal.

As I said, seriously, what can I do with the equipment I have to reduce chatter and make a nice looking crankshaft.

Thanks tons,

Tom, your humble beggar of advice.