- Joined

- Feb 1, 2015

- Messages

- 9,994

I bought the coolant system wth my Tormach 770. There is a sheet metal splash guard on either end of the table and an acrylic guard at the front. The column and the control panel at the back control splash in that direction. In addition, the tray has a guard on both sides and the back. I use a vinyl "shower curtain " held in place with magnets and that effectively controls and coolant splash as well aas chips even when using a facing mill. I wouldn't consider adding flood coolant to a lathe unless it was totally enclosed.

The coolant that I use is Premier Duracut from Tormach but I have seen good things said about Qualichem 251. I use flood coolant infrequently and have nit had a problem with it going rancid. Tramp oil is a problem. I manually skin the oil off the surface every so often. There are oil skimmers that will do that automatically. I have never had a problem with corrosion although I rinse the chips off the machine and wipe down the bare metal surfaces when done.

It is important to maintain the proper dilution. Too dilute and you will have corrosion problems. Too concentrated and you can strip paint off your machine. As coolant is used, water evaporates from the solution, increasing the concentration. The lost water must be replaced in order to maintain your proper concentration. For that, a Brix refractometer is essential. They needn't cost much. I bought mine on eBay for less than $20. The Brix scale is a measure of sugar concentration and is used in wine making. It does so by measuring the index of refraction of the solution. There is no definitive relationship between sugar water and coolant. If buying a Brix refractometer, you should buy one with the most sensitive scale. Mine is a 0 10 Brix.

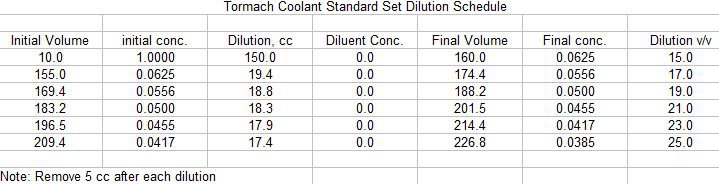

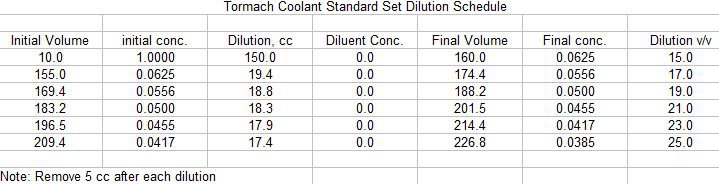

The refractometer should be calibrated by making up a few known concentrations of coolant solution and measuring the refractive index. With each new batch of coolant, I make up some standard solutions which I use for comparison. I make my solutions up by volume but they could just as easily be done by weight using a digital kitchen scale. Her ius a screen shot of the Excel spreadsheet that I use.

I keep a sample of each of the dilutions in a small vial so I can check the refractometer from time to time.

If I were making up samples by weight, I would first make up one at the concentration that I intended to use by weighing a known volume of concentrate and diluting it to the desired volume and weighing it. From that, I would know the conversion from volume/volume dilution to weight/weight dilution.Then I would make up my standards to bracket my desired dilution.

The coolant that I use is Premier Duracut from Tormach but I have seen good things said about Qualichem 251. I use flood coolant infrequently and have nit had a problem with it going rancid. Tramp oil is a problem. I manually skin the oil off the surface every so often. There are oil skimmers that will do that automatically. I have never had a problem with corrosion although I rinse the chips off the machine and wipe down the bare metal surfaces when done.

It is important to maintain the proper dilution. Too dilute and you will have corrosion problems. Too concentrated and you can strip paint off your machine. As coolant is used, water evaporates from the solution, increasing the concentration. The lost water must be replaced in order to maintain your proper concentration. For that, a Brix refractometer is essential. They needn't cost much. I bought mine on eBay for less than $20. The Brix scale is a measure of sugar concentration and is used in wine making. It does so by measuring the index of refraction of the solution. There is no definitive relationship between sugar water and coolant. If buying a Brix refractometer, you should buy one with the most sensitive scale. Mine is a 0 10 Brix.

Refractometer Brix 0-10% for sale | eBay

Get the best deals for Refractometer Brix 0-10% at eBay.com. We have a great online selection at the lowest prices with Fast & Free shipping on many items!

www.ebay.com

The refractometer should be calibrated by making up a few known concentrations of coolant solution and measuring the refractive index. With each new batch of coolant, I make up some standard solutions which I use for comparison. I make my solutions up by volume but they could just as easily be done by weight using a digital kitchen scale. Her ius a screen shot of the Excel spreadsheet that I use.

I keep a sample of each of the dilutions in a small vial so I can check the refractometer from time to time.

If I were making up samples by weight, I would first make up one at the concentration that I intended to use by weighing a known volume of concentrate and diluting it to the desired volume and weighing it. From that, I would know the conversion from volume/volume dilution to weight/weight dilution.Then I would make up my standards to bracket my desired dilution.