- Joined

- Oct 29, 2012

- Messages

- 1,387

I've burned through 2 rolls of Overture PC Professional trying to get results like these:

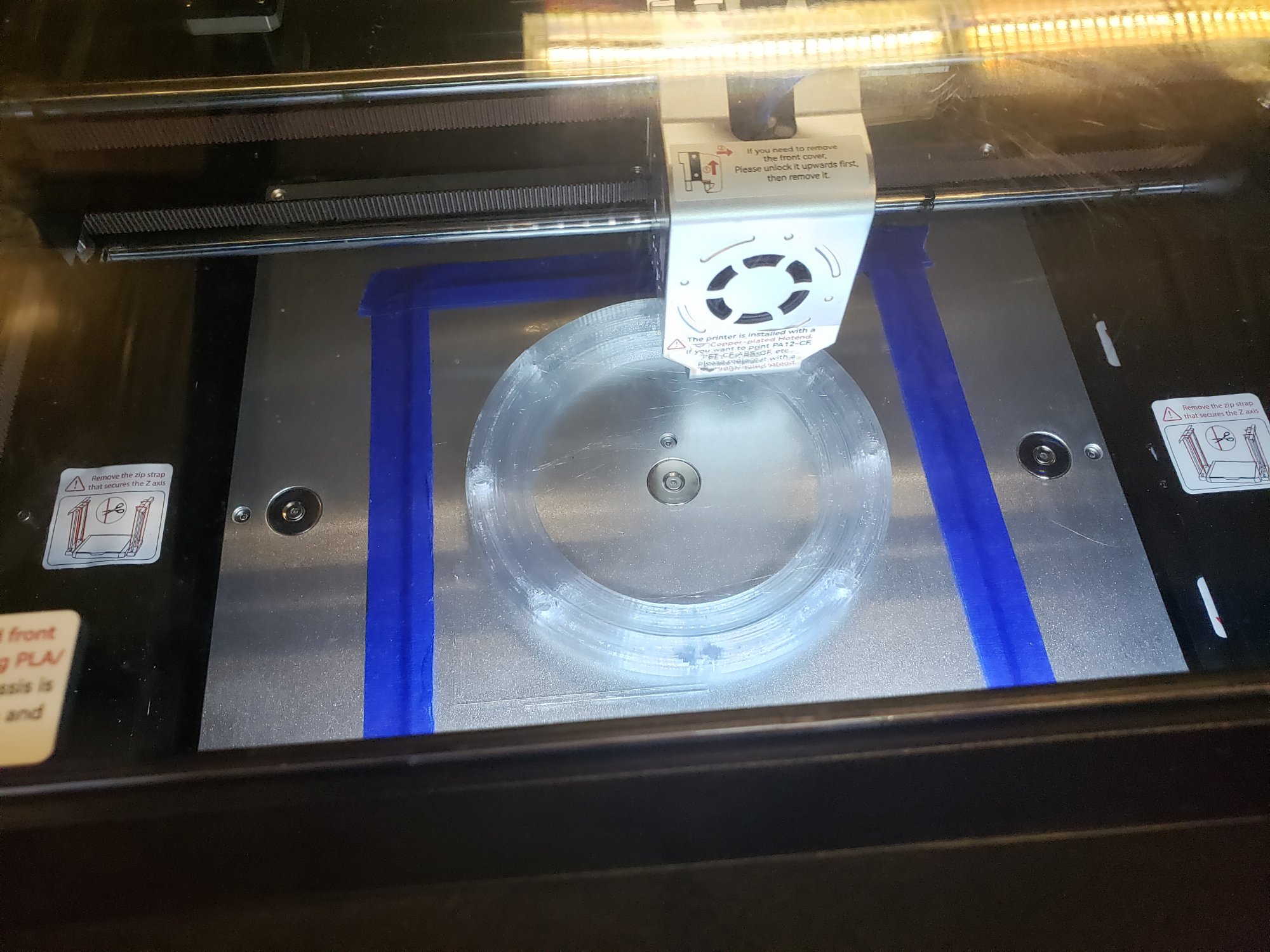

But the closest I've gotten is this:

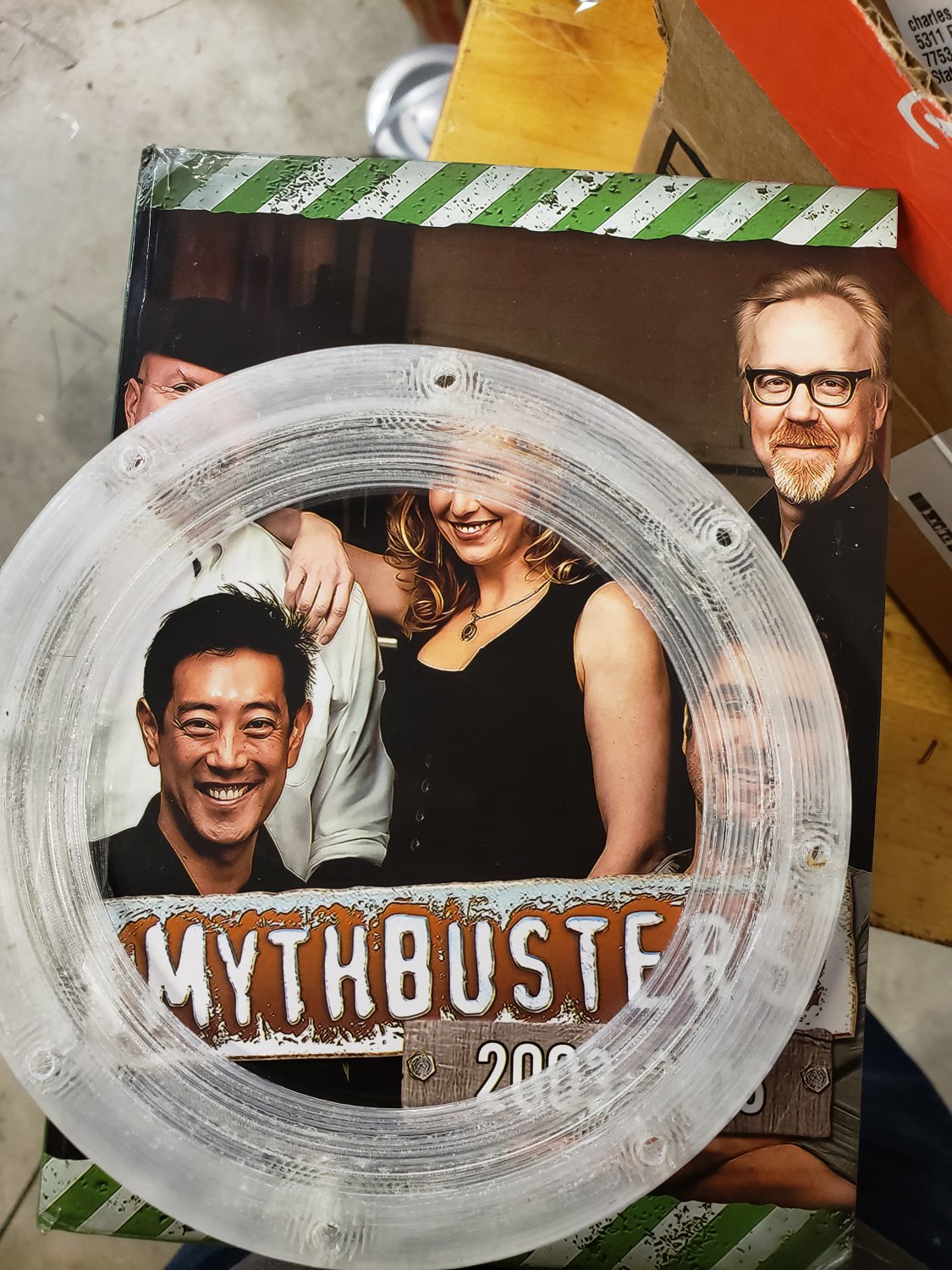

That looks almost acceptable but my typical result is more along the lines of this:

I followed the instructions in the link as a starting point but they are for PETG which behaves much differently than PC. I've tried all manner of ratios between layer height and width, all kinds of infill, nozzles of 0.4mm, 0.6mm, .8mm, both normal and CHT variety. Speeds from 20mm/s to 500mm/s, hot end Temps from 250C to 350C, build chamber temp from ventilated to 65C, tuned input shaping, tuned pressure advance, all kinds of stuff.

I can get it clear as glass as you look down through the top, down a column of stacked perimeters, up to an inch thick or more. But No matter what I do, the separation between columns, and the layer lines, form "walls" inside the part that obstruct the view. The layer lines can be removed from the outside by machining, sanding, and hitting them with a heat gun to make them clear in through the sides, but that's too much work and too risky. Too much heat gun and the part warps. The line between when it gets glass clear and when it turns into a Pringle is very fine.

I am going to try Polymaker Polylite in the morning, but if that doesn't work I'm giving up. That is, unless one of you fine folk can suggest something I haven't tried.

But the closest I've gotten is this:

That looks almost acceptable but my typical result is more along the lines of this:

I followed the instructions in the link as a starting point but they are for PETG which behaves much differently than PC. I've tried all manner of ratios between layer height and width, all kinds of infill, nozzles of 0.4mm, 0.6mm, .8mm, both normal and CHT variety. Speeds from 20mm/s to 500mm/s, hot end Temps from 250C to 350C, build chamber temp from ventilated to 65C, tuned input shaping, tuned pressure advance, all kinds of stuff.

I can get it clear as glass as you look down through the top, down a column of stacked perimeters, up to an inch thick or more. But No matter what I do, the separation between columns, and the layer lines, form "walls" inside the part that obstruct the view. The layer lines can be removed from the outside by machining, sanding, and hitting them with a heat gun to make them clear in through the sides, but that's too much work and too risky. Too much heat gun and the part warps. The line between when it gets glass clear and when it turns into a Pringle is very fine.

I am going to try Polymaker Polylite in the morning, but if that doesn't work I'm giving up. That is, unless one of you fine folk can suggest something I haven't tried.