Derek, I really like your attitude. You are going to find that many of the most experienced guys will pass on practical advice in a way that may sometimes come across as condescending. I'm almost sure that it is not meant that way; they are trying to help, just like most of us here are. In this case, they are right ... sorta'. Most stuff we make in a hobby shop (or even in a job shop) doesn't need to be made to fit specs so we can cut and fit to suit our needs. We don't need to use thread mics or wires. We cut the threads on one part and then cut the threads of the other part to fit that first one and we're done. I know you already know this so let me give you the stuff I think you're really after, knowing that you're trying to understand how screw cutting works.

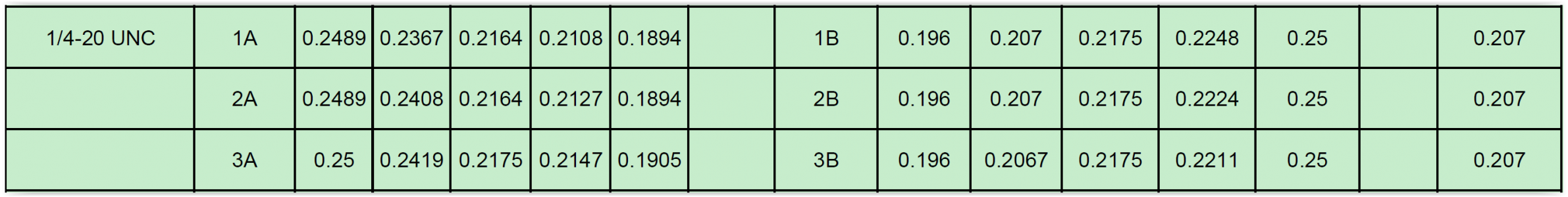

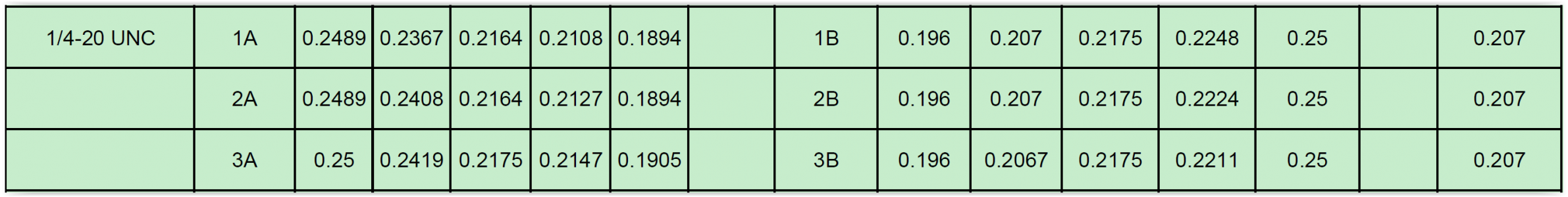

Screw cutting is actually very detailed and complex but in practice it isn't that difficult to understand. There is just a lot to know, and much of it can be found in a good table like the one I am attaching. The chart gives you all the practical information you need to cut threads, including the OD you need to turn your part to in order to cut a given thread. This OD depends on the class of thread you want. Most of the time, a class 2 fit is all we need. Sometimes we need a precision fit - a class 3 - and you will see that the range of diameters needed for each class changes. You choose the class you need and then turn your part to fall into that range of OD listed in the chart. Say you're turning a 1/4-20 thread:

Let's pick a class 2A (A means a male external thread) fit. Look at the numbers in the Major Diameter column. That Min/Max is the range of OD's your rod must be turned to in order to produce a class 2 fit, so you turn your rod until the OD is somewhere in the range between 0.2408 to 0.2489". Then you cut your thread. Now, in order to know how deep to cut you can calculate an estimate by using the formula 0.750/TPI, where TPI is the number of threads; in this case, 20, so 0.750/20 = 0.0375". So, you track your depths of cut as you cut your threads and well before you hit that total of 0.0375", you begin to check the thread pitch diameter with thread wires or a thread mic. The Pitch Diameter column will give you the range of diameters that will give you a class 2 fit. When you have cut deep enough for the pitch diameter to fall in this range, you're done.

Note also the last number, the Minor Diameter. That number is useful for cutting a thread relief. Just cut the relief about 0.005" deeper than the listed figure and about 2-3 threads wide.

As you can see, there is a lot more to cutting to specs so doing it this way is done only when it matters. For most things in a hobby shop, it won't matter; hence, the advice you got to just cut it until it fits. However, you should know how to cut it to fit when it does matter to you and I hope I made this a bit clearer for you. If not, say so and we'll go at it until it IS clear.