- Joined

- Dec 18, 2019

- Messages

- 7,428

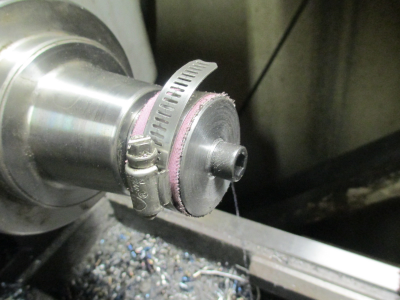

Since I'm a proud owner of a Niagara slitting saw, thought I'd make an arbor for it. Found a nice plan for a saw arbor @ saw arbor plan There are two pieces, the body itself and a close fitting cap.

How do I ensure the two pieces are concentric with each other? If machined them together, should one hold the cap end and put the shank end into a live center? Thought I'd machine it together as one piece and part the piece between the body and the cap. Both the body length and the cap length are not critical. Then put the body in a 4J chuck to bore out the 1.000" hole. At that point there will be an already turned cap to use to ensure a tight bore fit. Does this make sense?

As a beginner, it takes me a long time to think these kinds of things through. Appreciate any pointers to avoid lovely paper weights!

How do I ensure the two pieces are concentric with each other? If machined them together, should one hold the cap end and put the shank end into a live center? Thought I'd machine it together as one piece and part the piece between the body and the cap. Both the body length and the cap length are not critical. Then put the body in a 4J chuck to bore out the 1.000" hole. At that point there will be an already turned cap to use to ensure a tight bore fit. Does this make sense?

As a beginner, it takes me a long time to think these kinds of things through. Appreciate any pointers to avoid lovely paper weights!