I re-knurled some Jorgensen "Pony" clamps that way on the mill - it worked a treat:

Without a doubt, my favorite woodworking clamps are the 3700 series Pony bar clamps by Jorgensen. We use 'em in the guitar repair shop everyday, and basically live by the six-inch size for all kinds of routine clamping.

Doing some reorganizing, I recently came across a pair of 18-inch ones we'd labeled as unworkable because they wouldn't hold tight. They'd been put in the bad tools box decades ago with the idea that we'd eventually get around to using them for parts or something. Well today was the day for something.

In the foreground, it's one of the old clamps, and behind it, the new version. Notice that the "not tight" one is has no little grooves for the clutch plates to grip onto:

A while back, I'd seen a sale on these cheap little straight knurling tools, so I bought a pair for about ten bucks, figuring that "someday I'd use 'em for parts or something." Looks like that "someday" came along today, too:

I stuck the tool in a square 5C collet from the backside so I wouldn't have to remove the wheel to mount it on the lathe:

Then, I turned the shank down to 1/2" round for most of its length. If you look closely, you can see the live center at the right end:

I mounted the round shank in a collet so the shoulder would bear against the front of the collet, and leaving the quill fully retracted, I cranked the mill table all the way up to press the knurl wheel against the clamp bar supported on a parallel in the mill vise:

Cranking back and forth along the X-axis, I raised the table to get enough pressure to start the knurling process, working a six inch section at a time, reclamping the bar in the vise as needed.

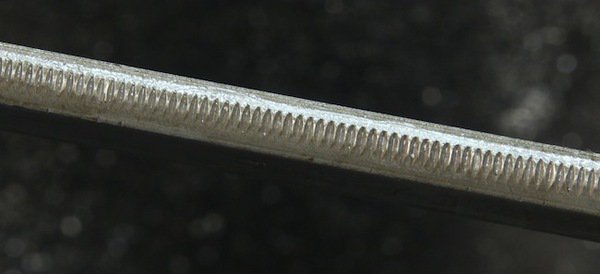

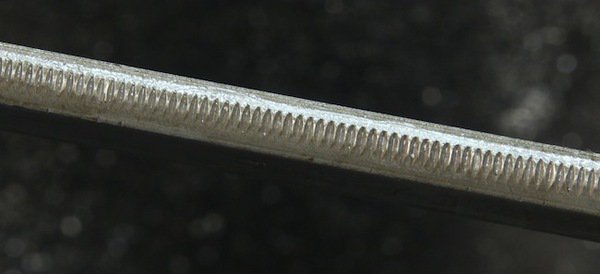

Came out pretty neat, yes?

Now the old "loose" clamps work as well as their younger counterparts.

http://www.frets.com/HomeShopTech/Tooling/MillKnurl/millknurl.html