-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another gear ?

- Thread starter Bob Kelly III

- Start date

- Joined

- Oct 11, 2019

- Messages

- 139

Humm....

Well that may well be !

....but I maintain that I did it ! LOL !

a bit ago I went out to the shop and changed the fly cutter profile using the angle grinder in the bench vice.... that grinding wheel was more the shape I needed than the one on the grinder....

I went ahead and chucked it up and gave it a try and I cut 3 teeth.... double checking between each tooth to make sure I was lined up correctly

....and I am glad I double checked as on the 2nd tooth I had to move the quill up about 3 or 4 thousandths as it wouldn't go into the bad gear all the way.... it hasn't changed sense and each tooth cut after that fell right into place like it should..... I only cut 3 or 4 teeth as I was tired and gave it up

but I did enough to realise that it is working great ! the depth of cut is surprisingly easy ! it's 100 thow deep ! but I am taking it slow and easy because I want this one to be the last one I make ! and at 5 thow a cut it takes a while...

but the jig is working fantastically..... although I may have to drill another alignment hole in the aluminum gear so I can rotate the bad teeth to the back side again as I am nearing that area now..... I dunno about that I will see when I get to that section and decide if I need to avoid it or not.

( i don't think i will have to )

.....

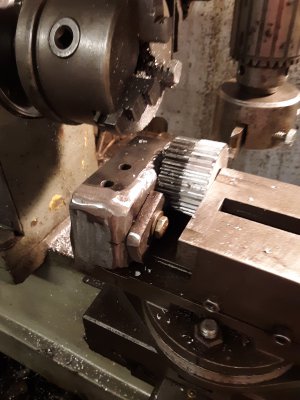

so I am now cutting the 34 teeth in the aluminum gear blank on the 3 in 1's Mill....

although I cannot tell if the gear teeth mesh good yet because I don't have enough teeth cut at the moment i do expect to have to dress it up with a bit of file work.

....

I couldn't practice on the old gear blank as it needs the bushing in it to fit the shaft properly and that bushing is now in the bad gear again and I didn't want to remove it another time ! .... so I just started in on the good gear blank, triple checked everything on the first cut and went just slightly too deep on the first tooth..... not enough to worry about at all. but the cutter kissed the Steel gear and I didn't want to do that.

at the rate I am going it will take me 3 days to cut all 34 teeth in this thing.... HAHAHAHHA ! but if it saves me $117.00 plus shipping it is worth it !

.....

but the beauty of this is making a completely new gear ! WITHOUT a dividing head or indexing machine that it would normally call for !

....

and Yes, I will post a few pictures when I am done !

....because I am sure there are others out there that have a lathe but no Mill.... and I am certain this can be done by using the lathe as the mill

the setup will have to be a bit different but whatever it takes right ?

.....

later all !

Bob.........

Well that may well be !

....but I maintain that I did it ! LOL !

a bit ago I went out to the shop and changed the fly cutter profile using the angle grinder in the bench vice.... that grinding wheel was more the shape I needed than the one on the grinder....

I went ahead and chucked it up and gave it a try and I cut 3 teeth.... double checking between each tooth to make sure I was lined up correctly

....and I am glad I double checked as on the 2nd tooth I had to move the quill up about 3 or 4 thousandths as it wouldn't go into the bad gear all the way.... it hasn't changed sense and each tooth cut after that fell right into place like it should..... I only cut 3 or 4 teeth as I was tired and gave it up

but I did enough to realise that it is working great ! the depth of cut is surprisingly easy ! it's 100 thow deep ! but I am taking it slow and easy because I want this one to be the last one I make ! and at 5 thow a cut it takes a while...

but the jig is working fantastically..... although I may have to drill another alignment hole in the aluminum gear so I can rotate the bad teeth to the back side again as I am nearing that area now..... I dunno about that I will see when I get to that section and decide if I need to avoid it or not.

( i don't think i will have to )

.....

so I am now cutting the 34 teeth in the aluminum gear blank on the 3 in 1's Mill....

although I cannot tell if the gear teeth mesh good yet because I don't have enough teeth cut at the moment i do expect to have to dress it up with a bit of file work.

....

I couldn't practice on the old gear blank as it needs the bushing in it to fit the shaft properly and that bushing is now in the bad gear again and I didn't want to remove it another time ! .... so I just started in on the good gear blank, triple checked everything on the first cut and went just slightly too deep on the first tooth..... not enough to worry about at all. but the cutter kissed the Steel gear and I didn't want to do that.

at the rate I am going it will take me 3 days to cut all 34 teeth in this thing.... HAHAHAHHA ! but if it saves me $117.00 plus shipping it is worth it !

.....

but the beauty of this is making a completely new gear ! WITHOUT a dividing head or indexing machine that it would normally call for !

....

and Yes, I will post a few pictures when I am done !

....because I am sure there are others out there that have a lathe but no Mill.... and I am certain this can be done by using the lathe as the mill

the setup will have to be a bit different but whatever it takes right ?

.....

later all !

Bob.........

- Joined

- Oct 11, 2019

- Messages

- 139

I sped up the mill to about 1000 RPM from the 450 it was at .... trying to speed up the process a bit.

I got 10 teeth cut today though I only was in the shop for about an hour and a half.

I found that I have to check the cutter placement on each tooth.... strangely enough.... I suppose the small amount of slop in the gear tooth at the back of the jig and very small amounts of difference between taking the jig out and putting it back in and clamping it down is enough for small variances

....

Bob.......

I got 10 teeth cut today though I only was in the shop for about an hour and a half.

I found that I have to check the cutter placement on each tooth.... strangely enough.... I suppose the small amount of slop in the gear tooth at the back of the jig and very small amounts of difference between taking the jig out and putting it back in and clamping it down is enough for small variances

....

Bob.......

- Joined

- Oct 11, 2019

- Messages

- 139

- Joined

- Oct 11, 2019

- Messages

- 139

Success ! the gear is done and with some hand filing it meshes great.... put it in the Logan 922 and it's never sounded so good ! much quieter!

....

to celebrate I did a little single point threading on some scrap PVC and I've never turned out such good looking threads before ! LOL

so the gear was a success....

I guess we shall see how long it lasts under my punishment !

.....

My Dog just got sprayed by a skunk... I sprayed him real good with vinegar and that has helped allot but "Cough ! Cough ! it's strong in here !

.....

vinegar is by far the best thing I've found for "Skunk" but it can only do so much !

and Yah he got it right in the face ! now maybe he will listen to me when I say leave that skunk alone !!!!

.....

HEHEHHEHE

Bob.....

....

to celebrate I did a little single point threading on some scrap PVC and I've never turned out such good looking threads before ! LOL

so the gear was a success....

I guess we shall see how long it lasts under my punishment !

.....

My Dog just got sprayed by a skunk... I sprayed him real good with vinegar and that has helped allot but "Cough ! Cough ! it's strong in here !

.....

vinegar is by far the best thing I've found for "Skunk" but it can only do so much !

and Yah he got it right in the face ! now maybe he will listen to me when I say leave that skunk alone !!!!

.....

HEHEHHEHE

Bob.....

- Joined

- Dec 31, 2010

- Messages

- 937

Thanks for the pictures. That is an amazing process, ingenious to say the least! Does turning the gear blank 180` mean you can only do even numbers of teeth?

Have a good day

Ray

Have a good day

Ray

- Joined

- Oct 11, 2019

- Messages

- 139

I don't believe so... because turning the gear 180 deg. is just putting the newly ground tooth slot in the pinned position for the next tooth to be cut.

.....so your doing one tooth at a time..... I really don't know <grin>

......

However that is not the method I used to make my aluminum gear from scratch, I used the double gear method and more or less just copied the teeth of the gear beneath the aluminum blank ... sense the aluminum gear blank is Pinned to the old gear I am copying, all I had to do is make sure the old gear had a pin or stop to keep it from turning.... and then use that to re position the 2 gears after each cut.

.....

I must admit that putting it in and taking it out of the milling vice 34 times was a tedious process indeed ! i will be real nice to that gear and be real careful with it because I do NOT want to make another one ! LOL......

.... if anyone out there is thinking of doing what I did with a homemade fly cutter....think again ! it would be 10 times better if you just bought the gear cutter and made your own arbor to fit the cutter ! ..... I used what I had in pure Ranch hand fashion.... in the end I noticed that my hunk of file I had so carefully shaped ( but was still quite a bit off ) had cracked and broke long ways..... rendering the cutter useless after this use. but it did the job that is what counts. because I shaped the cutter by eye and used no measuring instruments at all, I wound up having to file every tooth on that gear by hand

....if I would have used the correct cutter to begin with that would not have happened...so lesson learned !

....

as a side note .... I notice at about tooth 31 that the milling vice was flexing quite a bit as I clamped down on it real tight

I couldn't see anything wrong but when the gear Jig was removed the vice itself had alot of play in it..... so I investigated to find that the gib had slid out the back of the vice and was butted up against the end of the vice.... leaving the front half of the vice with alot of play...

that repaired and gib tightened fairly snug I finished the teeth cutting with no more issues !

.....that has been the most extensive use of that vice in the 3 in 1 in its entire lifetime,..... and I also find that the front gib screw is stripped out !

so I got more repair work to do ! the 3 in 1 has been a lifesaver on the Ranch and now it just saved the Logan 922 so all in all it has been a good tool even though it is way too small ! it was the cheapest Mill,Drill,Lathe that Harbor freight had about 30 years ago . and it's still going strong.

....

later all

Bob......

.....so your doing one tooth at a time..... I really don't know <grin>

......

However that is not the method I used to make my aluminum gear from scratch, I used the double gear method and more or less just copied the teeth of the gear beneath the aluminum blank ... sense the aluminum gear blank is Pinned to the old gear I am copying, all I had to do is make sure the old gear had a pin or stop to keep it from turning.... and then use that to re position the 2 gears after each cut.

.....

I must admit that putting it in and taking it out of the milling vice 34 times was a tedious process indeed ! i will be real nice to that gear and be real careful with it because I do NOT want to make another one ! LOL......

.... if anyone out there is thinking of doing what I did with a homemade fly cutter....think again ! it would be 10 times better if you just bought the gear cutter and made your own arbor to fit the cutter ! ..... I used what I had in pure Ranch hand fashion.... in the end I noticed that my hunk of file I had so carefully shaped ( but was still quite a bit off ) had cracked and broke long ways..... rendering the cutter useless after this use. but it did the job that is what counts. because I shaped the cutter by eye and used no measuring instruments at all, I wound up having to file every tooth on that gear by hand

....if I would have used the correct cutter to begin with that would not have happened...so lesson learned !

....

as a side note .... I notice at about tooth 31 that the milling vice was flexing quite a bit as I clamped down on it real tight

I couldn't see anything wrong but when the gear Jig was removed the vice itself had alot of play in it..... so I investigated to find that the gib had slid out the back of the vice and was butted up against the end of the vice.... leaving the front half of the vice with alot of play...

that repaired and gib tightened fairly snug I finished the teeth cutting with no more issues !

.....that has been the most extensive use of that vice in the 3 in 1 in its entire lifetime,..... and I also find that the front gib screw is stripped out !

so I got more repair work to do ! the 3 in 1 has been a lifesaver on the Ranch and now it just saved the Logan 922 so all in all it has been a good tool even though it is way too small ! it was the cheapest Mill,Drill,Lathe that Harbor freight had about 30 years ago . and it's still going strong.

....

later all

Bob......

It didn't happen without pics !

It didn't happen without pics !