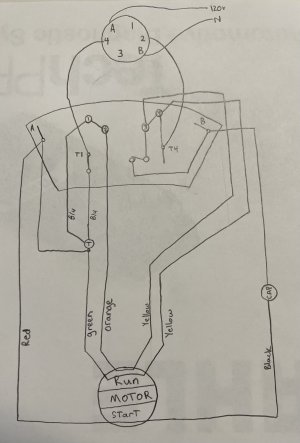

So far, a lot of "foo fah rah" that hasn't told you much. Let's back up a little and start from scratch. First off, never mind the switch, just consider the motor. A single phase motor will have two windings, the RUN and the START. In a dual voltage motor, the RUN winding may be in two parts. In that case, choose whether you want to run 120 or 240 volts. The RUN windings will be paralleled for 120 volts, seriesed for 240. The START winding

usually is 120 volts only. If 120 volts it will be connected at one end, if 240 it will be connected in the middle, at the common termination of the two RUN sections.

The motor

can be run on the bench without the START winding connected. The motor must be started by rotating the shaft in the desired direction. And done so within a couple of seconds, quickly so the magic smoke doesn't get out. This is handy for determining which end of the RUN winding section is which. Tests are done on 120 volts, of course. Even if the motor is to be run on 240, it can be tested on 120, so long as it isn't connected to a load.

Now to look at the START winding. This will consist of the

START winding proper, a capacitor, and a centrifugal switch, all in series. The complete circuit will connect to the RUN winding on one end (or in the middle for 240) and the line on the other. Direction of rotation is determined here, by swapping (reversing) these two leads. It doesn't matter which item is where in the series circuit, just that all three are there.

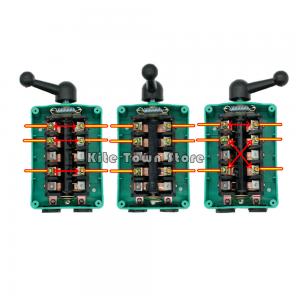

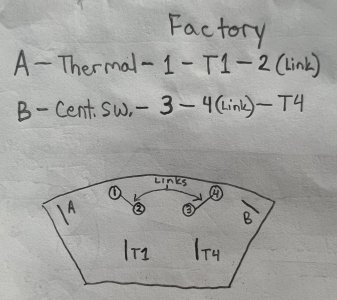

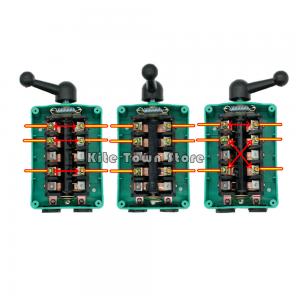

Now we can go into the switch. I will illustrate a switch that I have used on several machines. It is

NOT like the Furnas but will illustrate the concepts I need to convey. The switch will actually consist of three sets of contacts. This is where the VOM (Ohm Meter) will pay for itself. Or simply a buzzer and battery will suffice. Any sort of continuity tester. . .

With the switch centered, there should be no connection anywhere, a given. When the switch is thrown in either direction, there is

one set of contacts that will make up the same in both directions. That is the line switch, between the line and the motor.

In the photo above it is the top of the three. It will be

different on the Furnas, as well as Sq D and many other switches. That leaves the other two switches as a "reversing" pair. On the illustrated switch, the START winding will connect to one side of the switch, the other side connecting to the motor. Where and how the connections are made will be different for most drum switches. But the function will be the same for all. The premise will be to reverse the relationship of the START winding to the RUN winding, reversing the motor direction of rotation.

It

must be remembered that for

single phase motors, reversing can only take place when the motor is at or near zero speed. Slow enough to close the centrifugal switch. Unlike a three phase motor, where the "T" leads can be swapped at any speed, reversing the motor. But many (most?) of us are "casual" users and don't have three phase power available.

EDIT:

According to the nameplate above, there will be six (6) leads available. Two

each for RUN winding sections, and two for the START sequence, a total of six(6). It will be up to you to determine which pair is which since the colors have been changed. Any two will be a pair, two pairs a winding, probably a RUN section. One pair will give an anomolous reading, depending on what type of meter is used to check continuity. That will be the START pair, I use a Simpson 260 and/or a Fluke 76. One an analog and one a digital, giving decidedly different reactions to a capacitor. Whatever reaction is given to the capacitor, that is the START pair. Once you have determined each pair, each winding, just follow the nameplate diagram. Changing colors where applicable. . .

.