- Joined

- Sep 5, 2013

- Messages

- 3,793

Well I finally have this thing to the point where I can sharpen an end mill — the end of an end mill anyway, not the helical parts. I’ve been pecking away it since Christmas, long before the COVID turned the world upside down, and I’m calling it good for a while.

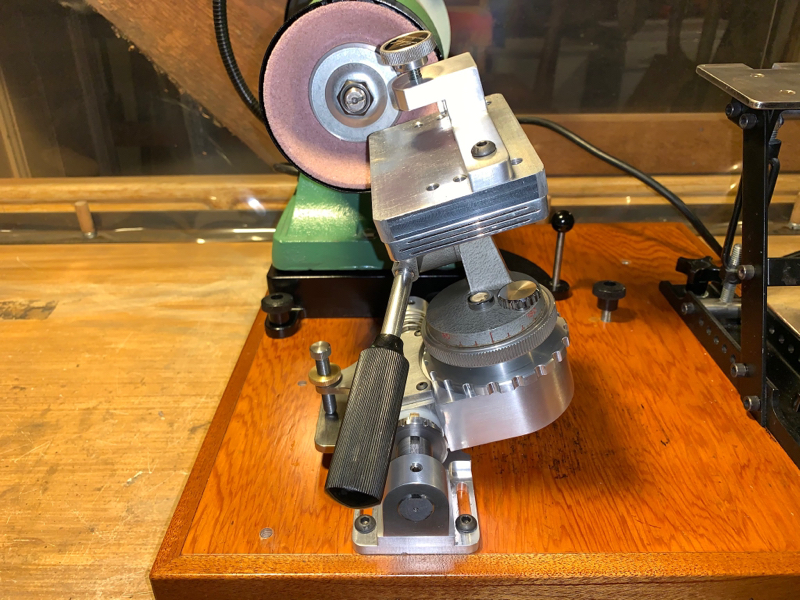

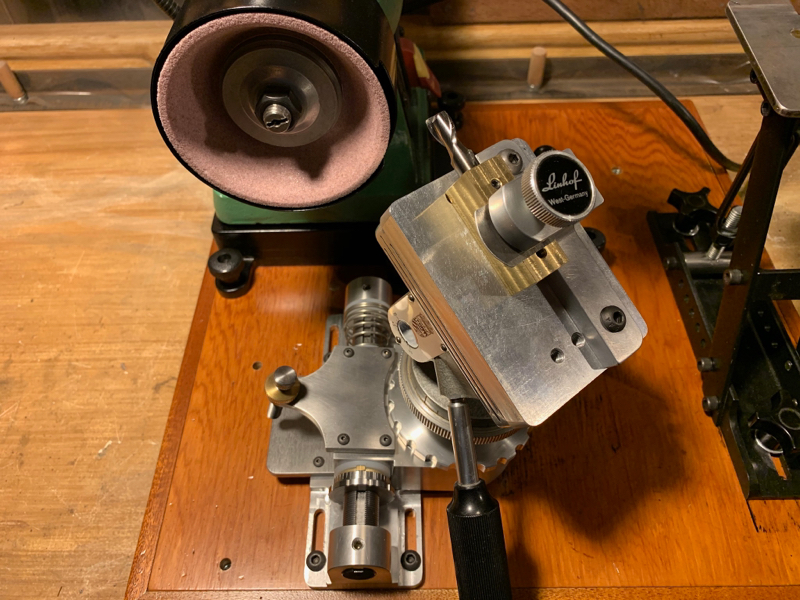

As with many things I build there’s often one or two back stories that have me taking the long way around. In this case I already had the basic grinder set up for sharpening lathe tools, that’s been working just fine for years, but the second half of the machine was one of those belt combo things that I never really got to liking much. I wasn’t using it, didn’t want to use it, so it would have to go. The other factor was to somehow repurpose a really nice Linhof pan-mount tripod head that had been languishing upstairs since my film cameras bit the dust. The end result, a marriage of the two as it were, is this grinding setup.

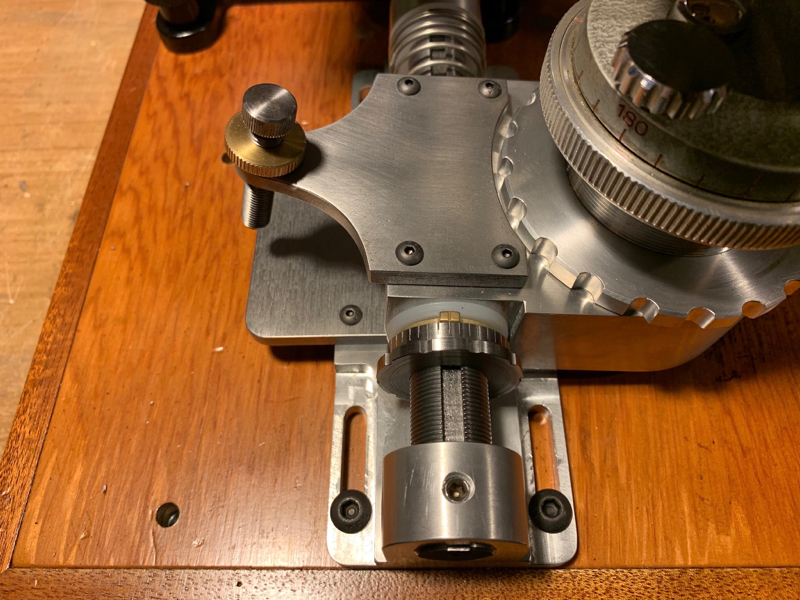

The main things I wanted to be able to do (in addition to my lathe and shaper tools which were already well in hand) was to touch up an end mill and sharpen cutters for the horizontal miller. Harold Hall covers both in his books and I did use some of his approaches albeit with a bit of modification. End mills still use a square carrier to index the cutting edges, but instead of sliding to approach the wheel I went with a pivoting motion. Travel is limited by an adjustable threaded stop.

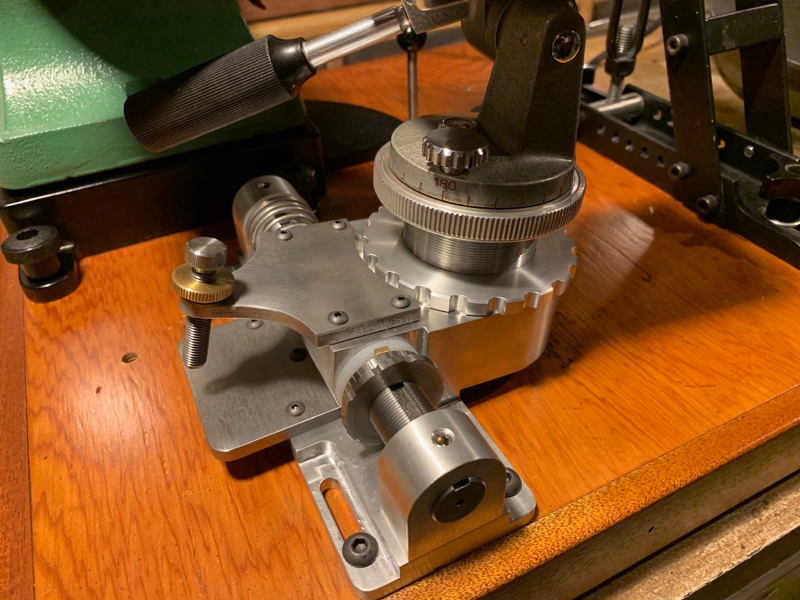

Proximity of the cutter to the wheel face can be adjusted in a couple of ways. Slackening four cap screws allows the entire mechanism to slide towards or away from the wheel for coarse positioning. Following that, there is a fine adjustment on the pivot shaft itself for more controlled advance of the head towards the wheel face. Each increment on the notched wheel advances the head by roughly one thousandth of an inch with an opposing coil spring providing a slight resistance.

The head can also be raised vertically (in relation to the wheel centreline) via the threaded column in the pivot yoke, it can slew a full 360 degrees independent of the height adjustment, and of course it can also pitch up / down using the extended tiller handle.

I spent quite a bit of time drawing all of the various parts and assemblies in detail using AutoCAD so that I could verify the different functions as I went along. One thing that set me back a little though was the ultimate size of the finished setup. The existing grinder and basic tool rest was set up on a suitably heavy wooden base that was nicely solid but still portable if need be. This new assembly would add a bunch more real estate off the opposite end of the grinder and I wasn’t really liking that. After about a month of hemming and hawing around I suddenly thought ‘okay, instead of mounting the new tool assembly off the end of the grinder and moving the whole base board to switch between operations, what happens if I mount both tool assemblies at the front and rotate the grinder to meet the applicable rest?’ This was the solution, and it works very well. Both tool rests remain positioned along the front edge of the wooden base and switching between one or the other is a simple matter of backing out four threaded knobs, pulling a locating pin and rotating the grinder ninety degrees, and dropping the locating pin and knobs back in again.

Still to come is a second tool holder plate that I can switch in for sharpening horizontal milling cutters and slitting saws. For now though I’ll use the setup as is and see if there’s any kinks that need working out along the way. Thanks for looking!

-frank

As with many things I build there’s often one or two back stories that have me taking the long way around. In this case I already had the basic grinder set up for sharpening lathe tools, that’s been working just fine for years, but the second half of the machine was one of those belt combo things that I never really got to liking much. I wasn’t using it, didn’t want to use it, so it would have to go. The other factor was to somehow repurpose a really nice Linhof pan-mount tripod head that had been languishing upstairs since my film cameras bit the dust. The end result, a marriage of the two as it were, is this grinding setup.

The main things I wanted to be able to do (in addition to my lathe and shaper tools which were already well in hand) was to touch up an end mill and sharpen cutters for the horizontal miller. Harold Hall covers both in his books and I did use some of his approaches albeit with a bit of modification. End mills still use a square carrier to index the cutting edges, but instead of sliding to approach the wheel I went with a pivoting motion. Travel is limited by an adjustable threaded stop.

Proximity of the cutter to the wheel face can be adjusted in a couple of ways. Slackening four cap screws allows the entire mechanism to slide towards or away from the wheel for coarse positioning. Following that, there is a fine adjustment on the pivot shaft itself for more controlled advance of the head towards the wheel face. Each increment on the notched wheel advances the head by roughly one thousandth of an inch with an opposing coil spring providing a slight resistance.

The head can also be raised vertically (in relation to the wheel centreline) via the threaded column in the pivot yoke, it can slew a full 360 degrees independent of the height adjustment, and of course it can also pitch up / down using the extended tiller handle.

I spent quite a bit of time drawing all of the various parts and assemblies in detail using AutoCAD so that I could verify the different functions as I went along. One thing that set me back a little though was the ultimate size of the finished setup. The existing grinder and basic tool rest was set up on a suitably heavy wooden base that was nicely solid but still portable if need be. This new assembly would add a bunch more real estate off the opposite end of the grinder and I wasn’t really liking that. After about a month of hemming and hawing around I suddenly thought ‘okay, instead of mounting the new tool assembly off the end of the grinder and moving the whole base board to switch between operations, what happens if I mount both tool assemblies at the front and rotate the grinder to meet the applicable rest?’ This was the solution, and it works very well. Both tool rests remain positioned along the front edge of the wooden base and switching between one or the other is a simple matter of backing out four threaded knobs, pulling a locating pin and rotating the grinder ninety degrees, and dropping the locating pin and knobs back in again.

Still to come is a second tool holder plate that I can switch in for sharpening horizontal milling cutters and slitting saws. For now though I’ll use the setup as is and see if there’s any kinks that need working out along the way. Thanks for looking!

-frank