- Joined

- Dec 25, 2011

- Messages

- 10,552

Ryan,

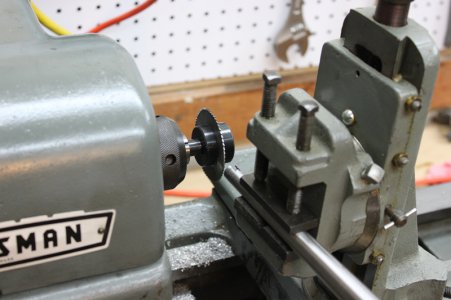

Although 3AT and 3C collets normally come in 1/32" increments and 3AT at least can be found in 1/64" increments, 2MT and 3MT collets commonly come in 1/16" increments. So decide what milling cutter and drill diameters you need and buy them with 1/16" increment shanks (and you will need to use single-ended milling cutters). Not much that you can do about drill bits below 1/4" except to use a headstock drill chuck. Buy 3MT collets with 3/8"-16 drawbar threads to fit the cutters.

1. I would buy one, myself, as I have other things I need to do. But...

2. Make the draw bar out of 3/8" round stock, not hex stock. It needs to be round at least on both ends, round stock is cheaper than hex, and there is no benefit to having it hex in the middle anyway. Cut the threads with a die nut. You only need about 3/4" threaded on the collet end. If you can borrow a tailstock die nut holder, you can use that and be able to say you did it on the lathe (in back gear). The Atlas has no brake, so if you try to thread the rod with a single point tool, you would probably need to cut a relief groove for the cutter runout or the main practice you would get would be in checking your blood pressure.

3. You could make the rod out of all thread but if you are going to make a drawbar, you may as well make it look decent. And you will be less likely to bend the solid rod than the all thread. Do not use a hex nut and wrench. If you do, you will soon come to hate it. And the first time that you forget and leave the wrench on the nut and turn on the motor, you will really hate it. Plus, you have to have something on the left end to hit when you want to remove the collet from the spindle (I use a piece of 2X4 oak block about 6" long.

Put a handwheel on the left end. Diameter between 2-3/4" (factory) and 3-1/2" (an aftermarket drawbar that I have). The left face of the handwheel should be approximately in the plane of the left vertical face of the gear cover up to an inch or so to the right of that. Between the left face of the spindle and the right face of the handwheel hub you need a spacer/thrust bearing. OD 1" to 1-1/4". ID 3/8". Length depends on design of the handwheel. Turn about 1/8" of the right end of the spacer down to a diameter of about 3/4" so that it is a slip fit into the spindle bore. This centers the drawbar in the spindle. You will see some spacers (including factory ones) for both drawbars and drawtubes that are beveled on the end instead of having a reduced diameter pilot. The latter works better all around, both when hooking up and tightening the collet, and when removing it from the spindle. With the beveled spacer, releasing the collet is a two hand operation. After looseining the hand wheel about two turns, you need to hold the beveled spacer into the slight countersink in the left end of the spindle while you hit the handle (and the knuckle of your right index finger) with a block or something. The piloted spacer will stay in place all by itself.

The length from the face on the left end of the spindle to the right end of the rod should be between 8-1/4" and 8-3/8". So the total rod length needs to be that plus an amount that will vary depending upon handwheel design.

Robert D.

Although 3AT and 3C collets normally come in 1/32" increments and 3AT at least can be found in 1/64" increments, 2MT and 3MT collets commonly come in 1/16" increments. So decide what milling cutter and drill diameters you need and buy them with 1/16" increment shanks (and you will need to use single-ended milling cutters). Not much that you can do about drill bits below 1/4" except to use a headstock drill chuck. Buy 3MT collets with 3/8"-16 drawbar threads to fit the cutters.

1. I would buy one, myself, as I have other things I need to do. But...

2. Make the draw bar out of 3/8" round stock, not hex stock. It needs to be round at least on both ends, round stock is cheaper than hex, and there is no benefit to having it hex in the middle anyway. Cut the threads with a die nut. You only need about 3/4" threaded on the collet end. If you can borrow a tailstock die nut holder, you can use that and be able to say you did it on the lathe (in back gear). The Atlas has no brake, so if you try to thread the rod with a single point tool, you would probably need to cut a relief groove for the cutter runout or the main practice you would get would be in checking your blood pressure.

3. You could make the rod out of all thread but if you are going to make a drawbar, you may as well make it look decent. And you will be less likely to bend the solid rod than the all thread. Do not use a hex nut and wrench. If you do, you will soon come to hate it. And the first time that you forget and leave the wrench on the nut and turn on the motor, you will really hate it. Plus, you have to have something on the left end to hit when you want to remove the collet from the spindle (I use a piece of 2X4 oak block about 6" long.

Put a handwheel on the left end. Diameter between 2-3/4" (factory) and 3-1/2" (an aftermarket drawbar that I have). The left face of the handwheel should be approximately in the plane of the left vertical face of the gear cover up to an inch or so to the right of that. Between the left face of the spindle and the right face of the handwheel hub you need a spacer/thrust bearing. OD 1" to 1-1/4". ID 3/8". Length depends on design of the handwheel. Turn about 1/8" of the right end of the spacer down to a diameter of about 3/4" so that it is a slip fit into the spindle bore. This centers the drawbar in the spindle. You will see some spacers (including factory ones) for both drawbars and drawtubes that are beveled on the end instead of having a reduced diameter pilot. The latter works better all around, both when hooking up and tightening the collet, and when removing it from the spindle. With the beveled spacer, releasing the collet is a two hand operation. After looseining the hand wheel about two turns, you need to hold the beveled spacer into the slight countersink in the left end of the spindle while you hit the handle (and the knuckle of your right index finger) with a block or something. The piloted spacer will stay in place all by itself.

The length from the face on the left end of the spindle to the right end of the rod should be between 8-1/4" and 8-3/8". So the total rod length needs to be that plus an amount that will vary depending upon handwheel design.

Robert D.