- Joined

- Oct 31, 2016

- Messages

- 2,720

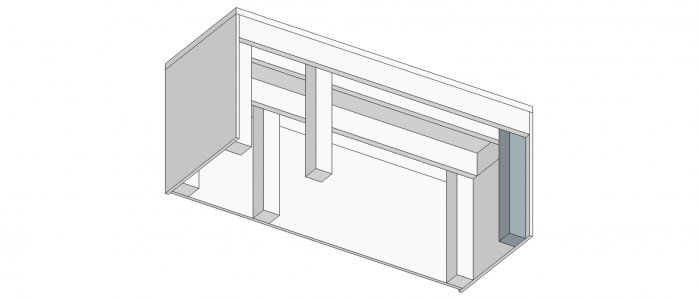

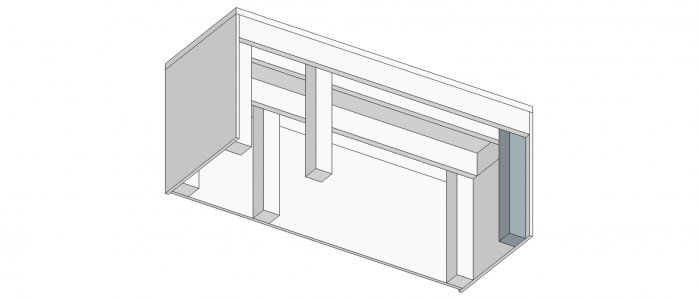

The strength is easy to achieve. Mass and rigidity is why you want big and heavy. The majority of the weight is at the headstock end. So you need additional support/mass at that end of the stand. If I was building a stand for a 1000 lb lathe it would look something like this. I know some/most will scoff at this but you could even make it out of wood. 4x4 posts, 2x6 runners, 3/4 plywood for the sides and back and 2 layers of 3/4 plywood for the top. The plywood glued and screwed with the posts and runners held together with bolts. Wood absorbs vibration better than steel. Make leveling feet for the posts. Something to thing about.

As an aside. As I look at stuff online invariably people who work in metal always seem to want to make everything out of metal and people who work with wood always want to make things out of wood. I try to think more along the lines as to what is the best material for the project at hand. I tend to favor wood for things like stands and benches because it is easier for me to work with.

As an aside. As I look at stuff online invariably people who work in metal always seem to want to make everything out of metal and people who work with wood always want to make things out of wood. I try to think more along the lines as to what is the best material for the project at hand. I tend to favor wood for things like stands and benches because it is easier for me to work with.