- Joined

- Mar 26, 2018

- Messages

- 8,639

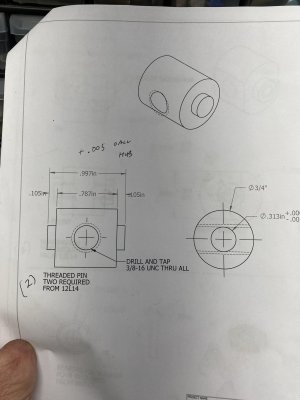

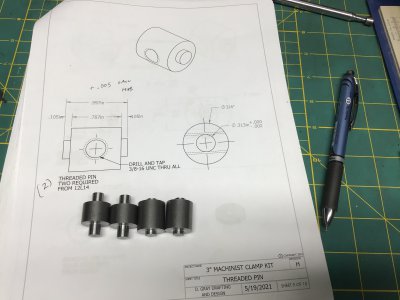

It’s on the print.Bet it will work anyhow. How was the .002 tolerance determined?

Plus, I want to hit the targets.

This is where you get to know your machine.

In order to measure the spacer, I had to take it out of the collet, determine how much more to cut then try to get the single point tool just touching the shoulder.

I must have got it wrong.

The tolerances are the challenge,fun but frustrating.