I've got all the parts for a Touch DRO install on my PM 1130-V lathe either here or on the way. Was thinking about the installation. I've been planning to make the mounting parts out of aluminum.

I'm cheating and doing a fairly close copy of Blondihack's install:

Her video describes the process and parts more completely, but the quick summary of the mounting parts is:

Is it OK to mix aluminum and cast iron for something like this? Most (but not all) of the lathe surfaces are painted which should minimize the opportunities for electrolytic corrosion. Most of the steel (12.9) bolts go thru clearance holes in the aluminum and thread into the lathe.

I'm cheating and doing a fairly close copy of Blondihack's install:

Her video describes the process and parts more completely, but the quick summary of the mounting parts is:

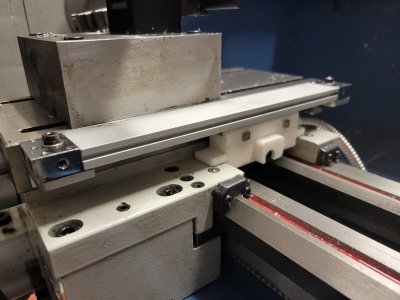

- I may use a block at each end of the long scale between the lathe and scale as I need a bit of space to clear some raised bosses. I might be able to use washers, but I'd like to have a place at each end to mount the scale and a cover w/o Swiss-cheesing the lathe with multiple holes.

- There's an L bracket to mount the optical read head that bolts to the saddle.

- On the cross slide, I'll need to support the magnetic read head with a block to elevate it over the carriage a small amount.

- Also on the cross slide, I'll need to extend the slide portion beyond its back by about three inches (because the read head mounts on the back side of the carriage).

Is it OK to mix aluminum and cast iron for something like this? Most (but not all) of the lathe surfaces are painted which should minimize the opportunities for electrolytic corrosion. Most of the steel (12.9) bolts go thru clearance holes in the aluminum and thread into the lathe.