- Joined

- Sep 2, 2013

- Messages

- 379

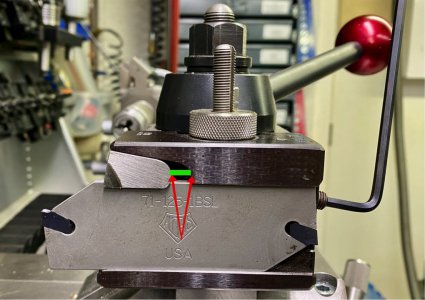

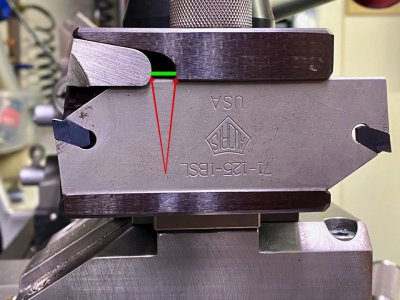

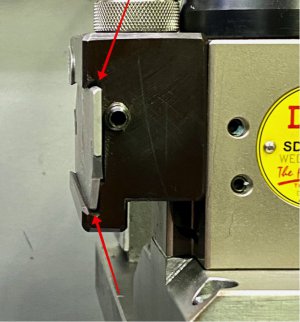

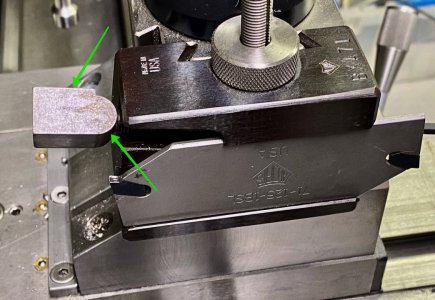

Does anyone have one of these? I bought an Aloris BXA-71 tool holder and an Aloris 71-125-1BSL blade today. See the attached picture, this 1 1/2" stick out is as close to the body that the blade end will tighten so it wont move. Other wise you can slide it back and forth. Is there a problem with the holder or am I not bright enough to figure out how to adjust this? I would prefer to have no more stick out than needed to do the cutoff.

Thanks in advance. Puzzled.

Rick

Thanks in advance. Puzzled.

Rick