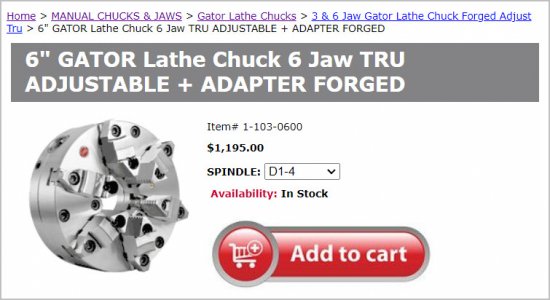

I forgot I posted that when I was evaluating the two brands. Interesting about the current price discrepancy. It appears the Gator includes the backplate in the price in the title description & drop down so it doesn't look like a typo. Best to call & confirm but I have also noticed Bison price creep as well. Once upon a time they used to be a good quality, half price alternative to higher end brands but times have changed. I have 5" 2-part jaw Gator chucks. Overall I would say 90% of Bison quality but most of that is finish. TIR is comparable & jaws fit well in the slots. The scroll wasn't quite as smooth but not horrible, being picky here. I've also heard its a moving target with them depending on when you purchased. QC kind of went up & down & up again. But seems like many Asian chuck makers are up-ing their game so maybe there is hope (and performance pressure).

On a related note, I tried posting a Set-Tru observation elsewhere, but this forum was having issues at the time so I don't think I ever went back to re-post. I have a Bison D1-4 ST in both 5C collet chuck & ultimately decided to buy the ST 6" 6-J chuck mentioned, luckily before the price increase. Using the radial adjusting set screws I dialed them in within a tenth & of course tightened the front retention bolts to retain that position, re-confirm TIR etc. I have a mark indicating the (D1-4) pins so they engage to the same spots each time. I carried on my merry way with no issues.

I normally use a regular 3J chuck for everyday work, so the ST's were on the shelf. When I remounted the 5C Set-Tru I knew something was fishy, it was off by 0.0035". I removed the collet & measured the 5C seat itself, exact same result & clock position. In other words runout was not due to the part or the collet. All the screws were tight including the front face screws. I reset concentricity using DTI, again within a tenth. About a week later I checked again, its off by 0.001". The lathe spindle is accurate so no issues there. Same test method, same test apparatus, same shop temp etc.

I've been repeating the same test with my Set-Tru 6J chuck. Its a similar effect but not to same degree. Drift is say 0.0010 - 0.0015". If it stays on the spindle I can't detect much change. So its almost like its stress relieving when off the lathe. Maybe because no spindle nose to offer support? Maybe thicker body 6" distorts less? I could not find a Bison torque spec for radial set screws, they just say equal. Lately I have been taking care to set them lighter, just enough to retain the position but avoiding overgronk especially because they must be very fine pitch. This seems to be helping although I'm not quite to the bottom of the issue. My conclusion is that these ST chucks are not set-and-forget. It just allows you to tweak & dial them in, which I suppose is better than regrinding jaws. Maybe I misunderstood this from the get-go. Tweaking them once or twice a year I'd be OK with, but if its very often, that's kind of a bummer for the cost.

Links. Bison just say 'equally tightened'

https://bison-chuck.com/wp-content/uploads/2021/06/Manual-3200_3500-1001-01.pdf

Very informative video by Rob Renzetti on chuck body distortion