Here we go...

Here is the paint job under way; it is finished now.

OK, you have seen the destroyed gear and the cleanup.

The saga continues, with a few pics of the rebuild of the missing gear.

What I find great is that I used the lathe to repair itself.

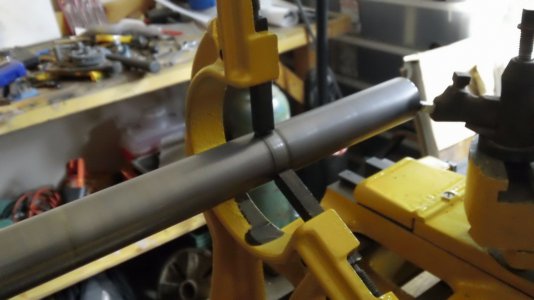

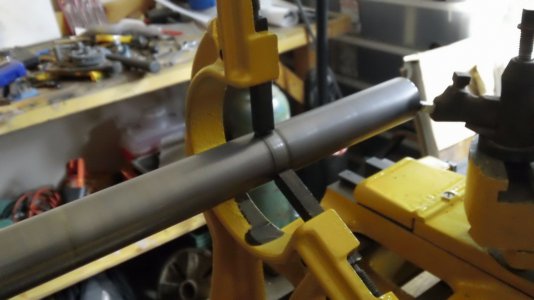

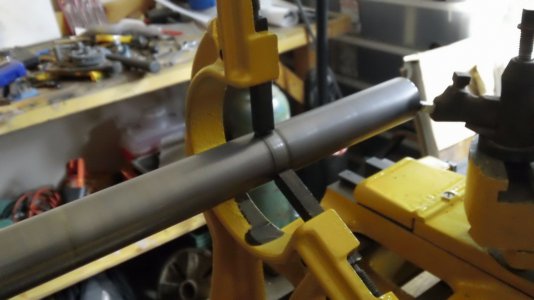

I started with a 1¼ CRS bar.

I had to learn how to grind a lathe tool, and it was

after these pictures. I grabbed what came with the machine, it just worked, not well.

I turned a bit more than the thickness of the parent gear to an exact fit (just a bit tighter than slip).

Side note here about the step pulley/motor pulley assembly at the top of the machine.

The arbor has a slot for a woodruff key. My (old) step pulley had a slot for a woodruff key.

I bought a complete assembly (different lathe, same step pulley), took it apart, same slots on both arbor an pulley, no key.

The Atlas parts list shows ... no key. It all hangs from a single set screw.

But if you try to put any kind of torque, like a parting job, the dang thing slips like Holiday on Ice.

This explains the strange look of the parted puck; the next day I got a key, installed it and everything is rock-solid, without gouging the arbor.

After parting the piece (see comment above) I "pressed" it in place (bench vise and mallet) with a drop of green Loctite 680.

Next came the drilling, boring and facing the set to the result here. It actually looks much like the original. I did not put a bushing, we'll see how it goes. That can be retrofitted if need be.

BUT! I was not able to put everything back together.

Once the second shaft was in the box, it locked up. After checking that everything else had correct play and turned freely I discovered ANOTHER bent gear.

It does not show much on the pictures, or in person, but most teeth of the smaller gear are bent.

I am trained for the exercise now, my replacement gear is in the mail, a few more pictures to come and hopefully the finished product.

although it is a project down the road.

although it is a project down the road.