- Joined

- May 20, 2014

- Messages

- 191

I plan to post a series of mods for the Atlas/Craftsman 6x18. Since they're machine specific, I guess they should go into this forum, instead of the 'projects' forum???

This little degree wheel fits on the spindle flange, behind the chuck.

And, just like the feedscrew dials, it gets frequent use.

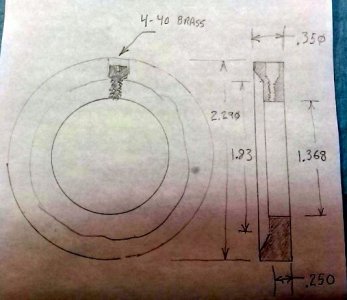

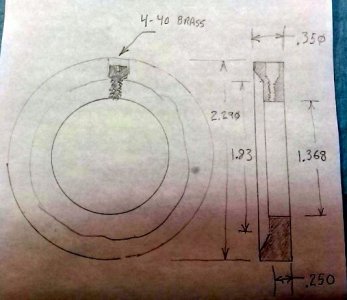

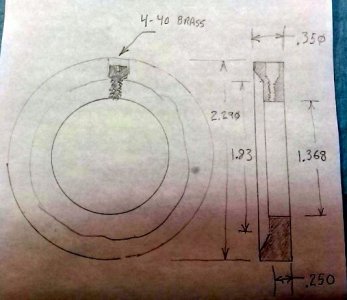

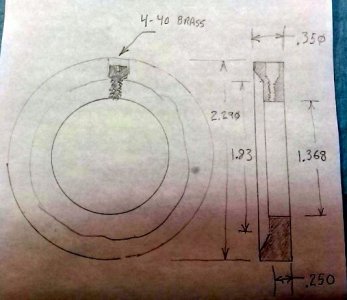

It's a simple disc of aluminum, 1/4" thick where it rides on the spindle flange, then flares around the headstock casting to a more visible 0.350" wide outer face.

The ID is slightly less than 1-3/8", because I skimmed the spindle flange OD to get a smooth light drag fit. Your flange diameter may be a bit larger, so adjust the ID dim to fit. You may need to skim your flange as I did.

The wheel needs some sort of grub screw, I used a small 4-40 brass screw with a larger head.

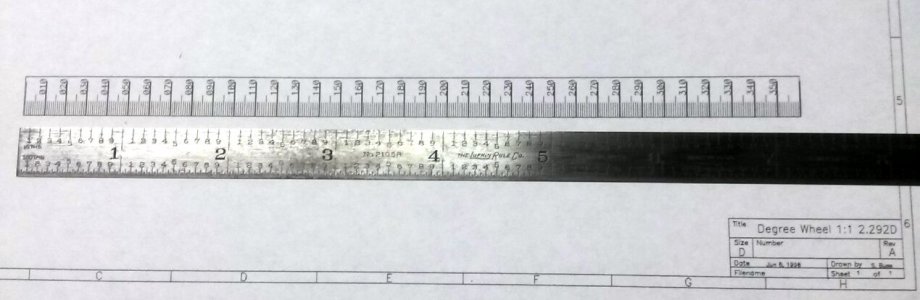

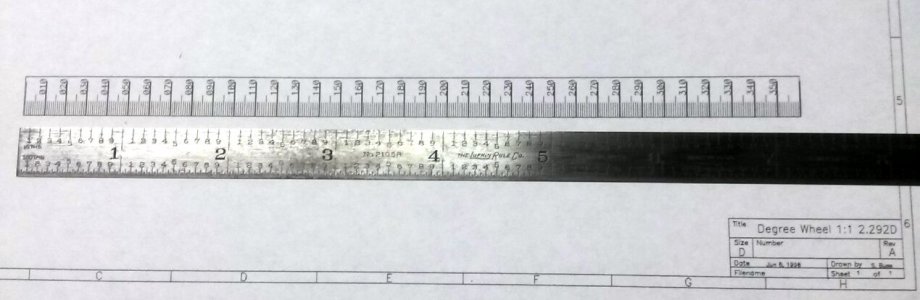

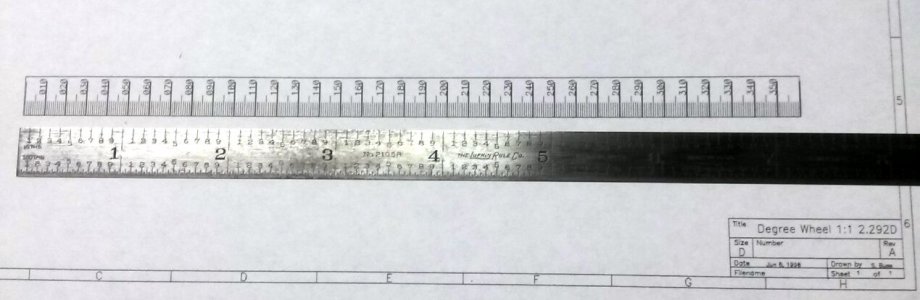

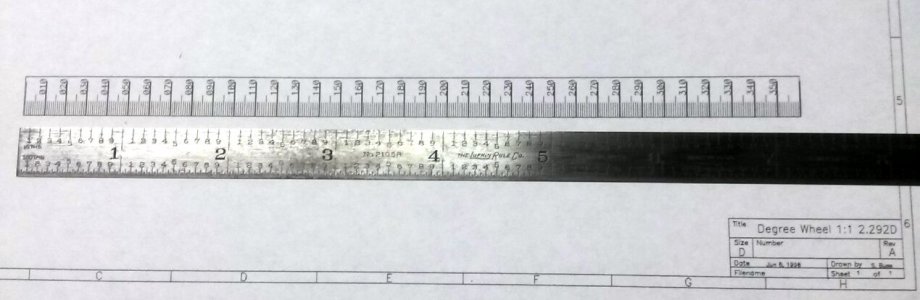

The wheel is marked for the full 360° by glueing a 0.400" wide strip of 7.200" long paper, pre-printed with the degree markings.

I made this back in the '90s, when inkjet printers had coarser dot densities. I wanted crisp/clear marking lines, and to achieve that I needed to select a printing size that would ensure that the inkjet dots aligned with the desired marking lines. A circumference of 7.200" would make each degree mark fall on a 0.020" dimension, which worked great for my 300 DPI (Dots-Per-Inch) inkjet printer. Divided by Pi, this makes the OD of the degree wheel 2.292". The printer paper is about 0.004" thick, and I found thru experimentation that an OD of 2.290" allowed the paper strip to perfectly wrap around the circumference.

This little degree wheel fits on the spindle flange, behind the chuck.

And, just like the feedscrew dials, it gets frequent use.

It's a simple disc of aluminum, 1/4" thick where it rides on the spindle flange, then flares around the headstock casting to a more visible 0.350" wide outer face.

The ID is slightly less than 1-3/8", because I skimmed the spindle flange OD to get a smooth light drag fit. Your flange diameter may be a bit larger, so adjust the ID dim to fit. You may need to skim your flange as I did.

The wheel needs some sort of grub screw, I used a small 4-40 brass screw with a larger head.

The wheel is marked for the full 360° by glueing a 0.400" wide strip of 7.200" long paper, pre-printed with the degree markings.

I made this back in the '90s, when inkjet printers had coarser dot densities. I wanted crisp/clear marking lines, and to achieve that I needed to select a printing size that would ensure that the inkjet dots aligned with the desired marking lines. A circumference of 7.200" would make each degree mark fall on a 0.020" dimension, which worked great for my 300 DPI (Dots-Per-Inch) inkjet printer. Divided by Pi, this makes the OD of the degree wheel 2.292". The printer paper is about 0.004" thick, and I found thru experimentation that an OD of 2.290" allowed the paper strip to perfectly wrap around the circumference.

Last edited: