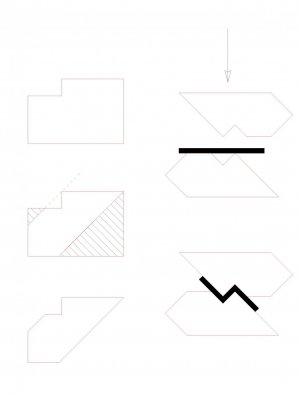

I need to make a piece from 1/8"-thick x 1/2" wide stainless bar. Here's what it looks like:

I need to duplicate this, except that the overall distance between the hole-centers needs to be 1/4" more than it is now.

The locknut attached to the back? I can do that with some JB-weld. The holes? No problem there, either, esp. since reading a discussion from H-M about how to use center-drills better.

But that zig-zag bend has me troubled. There's a bender at the shop, but it's for sheet-metal, and can't handle something like 1/8" stainless. There are a couple of arbor presses that I could use, and I've even got a 20-ton Harbor Freight hydraulic press at home ... but I don't really know how to use them to get what I want.

I figure that I can take a scrap piece of steel and cut a notch, rotated 45 degrees, making something like a vee-block. Then I can put my stock on top of it, and then put a rod on top of that, and press down on the rod so that it pushes the stock into the vee to get a decent bend. But then I need to flip it over and bend the OTHER way, and I don't see how to do that without interference with the rest of my "vee block".

There's also the challenge that the amount of offset is critical. It should be 0.5", although 0.45" would still be OK, I believe. More than 0.5" would be bad though.

The good news is that I have a fair amount of stock to practice with, and I figure I'll make the bends before drill the holes, etc.

Can folks suggest how to make a reliable amount of offset, and how to make the "zag" after I've made the "zig"?

By the way, you can see that this zig-zag isn't exactly 90-degrees -- more like a pair of 120-degree angles. And in fact, those angles aren't at all critical. I'm not sure whether that helps or not. I'd like to think that if I bent it 90 degrees, and found the offset was 0.6", I could "unbend" a little and make it 0.5, but my experience with work-hardening of stainless is that this will be more or less impossible.

BTW, the stainless I've got says "T-304L".

My gratitude in advance for any help folks can provide.

--John

I need to duplicate this, except that the overall distance between the hole-centers needs to be 1/4" more than it is now.

The locknut attached to the back? I can do that with some JB-weld. The holes? No problem there, either, esp. since reading a discussion from H-M about how to use center-drills better.

But that zig-zag bend has me troubled. There's a bender at the shop, but it's for sheet-metal, and can't handle something like 1/8" stainless. There are a couple of arbor presses that I could use, and I've even got a 20-ton Harbor Freight hydraulic press at home ... but I don't really know how to use them to get what I want.

I figure that I can take a scrap piece of steel and cut a notch, rotated 45 degrees, making something like a vee-block. Then I can put my stock on top of it, and then put a rod on top of that, and press down on the rod so that it pushes the stock into the vee to get a decent bend. But then I need to flip it over and bend the OTHER way, and I don't see how to do that without interference with the rest of my "vee block".

There's also the challenge that the amount of offset is critical. It should be 0.5", although 0.45" would still be OK, I believe. More than 0.5" would be bad though.

The good news is that I have a fair amount of stock to practice with, and I figure I'll make the bends before drill the holes, etc.

Can folks suggest how to make a reliable amount of offset, and how to make the "zag" after I've made the "zig"?

By the way, you can see that this zig-zag isn't exactly 90-degrees -- more like a pair of 120-degree angles. And in fact, those angles aren't at all critical. I'm not sure whether that helps or not. I'd like to think that if I bent it 90 degrees, and found the offset was 0.6", I could "unbend" a little and make it 0.5, but my experience with work-hardening of stainless is that this will be more or less impossible.

BTW, the stainless I've got says "T-304L".

My gratitude in advance for any help folks can provide.

--John