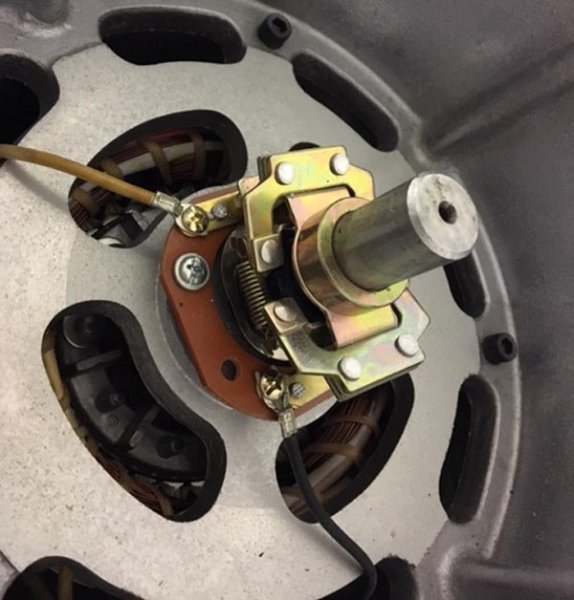

Well, I don’t know if I bought me some time or issue solved. Let’s hope for the latter. I figured there was nothing to lose to have a look-see of the centrifugal switch. I removed the motor end bell, plastic fan & this exposes the centrifugal switch & underneath that, the spring washer points plate. I noticed a glop of Loctite on the screw holding the CS onto the motor shaft so I first scribed a line on the shaft so I could replicate this vertical position because it’s very likely factory set against spring washer tension. Now was it set ‘correct’ to begin with & I mindlessly replicated I can’t say.

Once out, the CS action seemed relatively smooth. I couldn’t see any holdups or burs. It’s not exactly a Swiss watch, just stamped metal parts & press pins. But I couldn’t feel any noticeable snags or lockups.

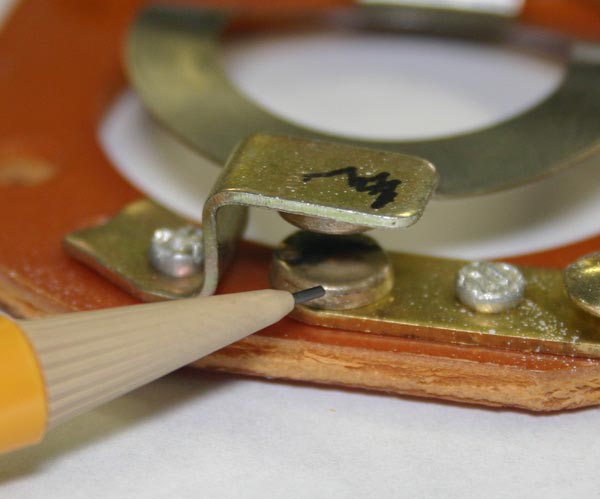

Next I removed the spring washer points plate out. For the most part looked pristine. But I noticed just a hint charcoal looking burn & teeny frags like pitting on maybe 40% of the disc. I figured what the heck, clean it up with an Emory board. They looked flatter & shinier when I was done but it was more just to clean them up while I was there.

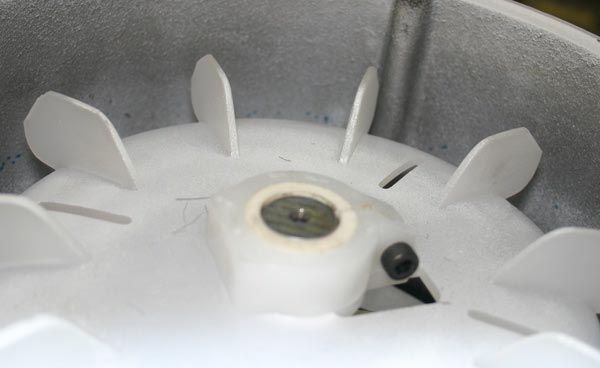

I put all the CS parts back the way they were. One thing I didn’t pay attention to was where the cooling fan was placed vertically when I removed it. Actually it was removed by the tech once before on episode-1 so likely not factory position anyway. It is retained on the shaft by a Philips M5 screw & nut which is cumbersome to remove. If you come at it with a long screwdriver it is possible to kind of slide the unit down trying to torque it. Hmm.. I wonder if maybe far enough down to conflict with the CS? So I swapped in a socket head cap screw so I could engage more positively & kept it high on the shaft with max clearance to CS. Buttoned everything up & figured WTF, plug it in & see if it cogs. Surprise. Smooth running motor. Aaaah. Tried it a dozen times in & out of gear, forward, reverse. Its like the problem never existed.

So I don’t know what to say right now. Maybe the points, maybe the fan position was the underlying problem. Or maybe this just bought me another 200 starts & the cogging will start again. Maybe I am just on the bubble of some cumulative effect of electrical issues stacking up the wrong way like +10% motor draw + 15% cap tolerance issue + + 5% N-Am line voltage issue + ??? maybe it might come to haunt me again. So I’m going to try & run the crap out of it now.

Thanks for your help & suggestions thus far. TBC.

Once out, the CS action seemed relatively smooth. I couldn’t see any holdups or burs. It’s not exactly a Swiss watch, just stamped metal parts & press pins. But I couldn’t feel any noticeable snags or lockups.

Next I removed the spring washer points plate out. For the most part looked pristine. But I noticed just a hint charcoal looking burn & teeny frags like pitting on maybe 40% of the disc. I figured what the heck, clean it up with an Emory board. They looked flatter & shinier when I was done but it was more just to clean them up while I was there.

I put all the CS parts back the way they were. One thing I didn’t pay attention to was where the cooling fan was placed vertically when I removed it. Actually it was removed by the tech once before on episode-1 so likely not factory position anyway. It is retained on the shaft by a Philips M5 screw & nut which is cumbersome to remove. If you come at it with a long screwdriver it is possible to kind of slide the unit down trying to torque it. Hmm.. I wonder if maybe far enough down to conflict with the CS? So I swapped in a socket head cap screw so I could engage more positively & kept it high on the shaft with max clearance to CS. Buttoned everything up & figured WTF, plug it in & see if it cogs. Surprise. Smooth running motor. Aaaah. Tried it a dozen times in & out of gear, forward, reverse. Its like the problem never existed.

So I don’t know what to say right now. Maybe the points, maybe the fan position was the underlying problem. Or maybe this just bought me another 200 starts & the cogging will start again. Maybe I am just on the bubble of some cumulative effect of electrical issues stacking up the wrong way like +10% motor draw + 15% cap tolerance issue + + 5% N-Am line voltage issue + ??? maybe it might come to haunt me again. So I’m going to try & run the crap out of it now.

Thanks for your help & suggestions thus far. TBC.

Last edited: