- Joined

- Apr 30, 2012

- Messages

- 2,401

hi

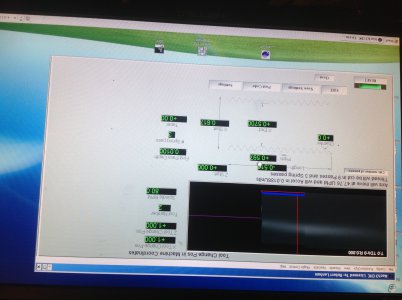

look at the pic on the screen it shows you starting at "0" and working out on the depth. notice the light blue is half of the material diameter.

x start is the diameter of the stock to be threaded 3/8 .375 (if your in diameter mode and you should use diameter mode the mach3 screen says the mode upper left)

x end equals the diameter of the stock minus the thread depth times 2

z 0 start should be the right end of your stock

z end is in minus like -1.000 if your going to thread 1 inch

tool change should be a positive z away from the end of your material like 1.000 or 1 inch to the right of the end of the stock

and x tool change should also be positive out away from your stock. in this case 1.0 is larger than the stock diameter of .375 and that should be safely clear of the stock.

there should also be another setting I think its "clearance or lead " and it is the distance out in front of the end of the stock to start the thread cycle so all the play has been taken up and spindle speed is settled in. it's normally about a tenth of and inch.

steve

look at the pic on the screen it shows you starting at "0" and working out on the depth. notice the light blue is half of the material diameter.

x start is the diameter of the stock to be threaded 3/8 .375 (if your in diameter mode and you should use diameter mode the mach3 screen says the mode upper left)

x end equals the diameter of the stock minus the thread depth times 2

z 0 start should be the right end of your stock

z end is in minus like -1.000 if your going to thread 1 inch

tool change should be a positive z away from the end of your material like 1.000 or 1 inch to the right of the end of the stock

and x tool change should also be positive out away from your stock. in this case 1.0 is larger than the stock diameter of .375 and that should be safely clear of the stock.

there should also be another setting I think its "clearance or lead " and it is the distance out in front of the end of the stock to start the thread cycle so all the play has been taken up and spindle speed is settled in. it's normally about a tenth of and inch.

steve