I'm a relative newbie myself, albeit with a few decades of hobby woodworking to draw on. I thought I had my clamping needs pretty much covered until yesterday - needed to reduce the diameter of a T-shaped wood-lathe toolrest's post from 3/4" to 1/2". Both arm and rest were eBay finds, and the arm's hole was too small for the rest. Why it's being mounted on a metalworking lathe is a story for another day.

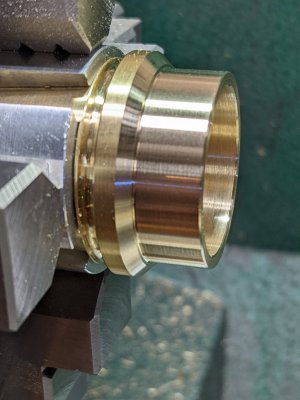

The finished product:

View attachment 432021

As you can see in the pic above, the rest's "T" arm was far too large for the shaft to be turned axially in that silly little lathe o' mine. My first thought had been to mount the T onto the lathe's carriage to feed the shaft horizontally past a boring head to shave it down. No luck with that, so next stop was a mill/rotary table setup: One V block, two clamping kits (mill bed + rotary table), some scrap brass and aluminum, a couple of parallels, a pocket rule acting as a shim, a handful of nuts, bolts, and washers landed me here. It literally made me laugh, hence the picture:

View attachment 432022

Absolutely ludicrous - but I was able to hang my weight off of the clamped part in any direction without it shifting. Upper right in the photo above is a roughing mill against the shaft being being turned down.

Fresh out of that setup, with a few lingering chips:

View attachment 432008

Lessons learned along the way: Need more threaded rod and nuts for my rotary table. Need a variety of shim stock. Need to go slowly, and stop and step back/assess often. Since yesterday I've thought of about six other approaches, including milling a one-off clamping fixture to match the angle of the T arm that bolted directly down to the rotary table, but this got it done.

I think Chipper 5783 nailed it, "Start with a good quality heavy milling vise and a clamp set. Then make and/purchase additional clamping devices - the additional items will go on indefinitely, so buy or make whatever you need as the task determines." (and have fun along the way).