- Joined

- May 21, 2022

- Messages

- 19

After finally managing to haul a Sheldon lathe out of the basement it was in for 50 years, it's back together in my garage with some fresh pain (pics to come elsewhere after I clean the garage ). I was able to play around with it a bit, but I have what I believe to be an electrical problem.

). I was able to play around with it a bit, but I have what I believe to be an electrical problem.

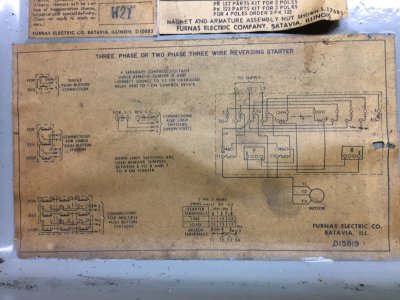

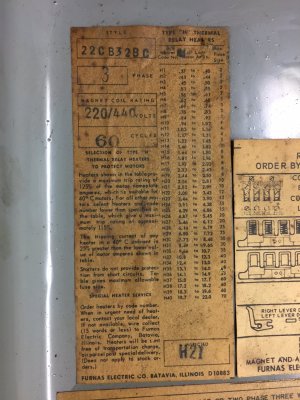

Setup: WM-56P with the original 2HP motor running off of a static phase converter on 220.

Problem: The overload is tripping left, right, and center...

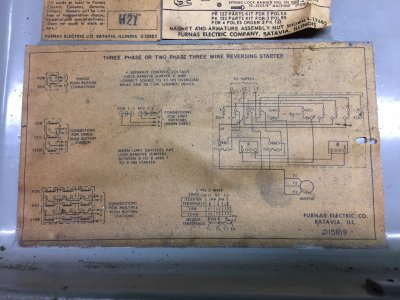

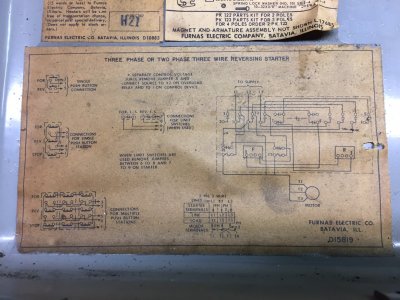

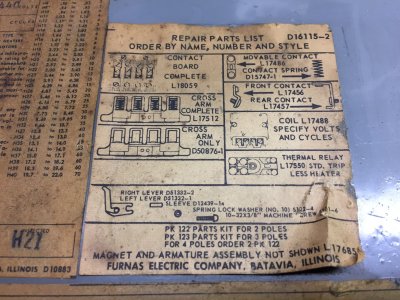

Whenever I try to either run the lathe at a higher speed, say over 1200 RPM, I start to hear the SPC kick in and out rapidly until the overload trips. At first, I thought it was a belt tension problem. So, I went through all the belts to make sure they had plenty of slack, but I was stuck with the same problem. Anytime I'd try to get up to speed, the overload would trip. I checked with a clamp on ammeter and saw it drawing 9.5 amps on 220 volts with just the chuck spinning at 1000 RPM. I tried disconnecting the motor belt to see what the draw was with just the motor but I was still seeing ~6 amps. The nameplate of the motor says 6.8 amps at 208 volts. It may be worth noting that I see 240 volts on the line side of the contactor with the lathe off, but that quickly drops to 220 volts once running. I don't think that's an issue but that's beyond me.

This is where the extent of my knowledge leaves me. I don't know what step to take next to find the problem. I'm not sure if the motor is somehow worn out, if I should try searching for a bad wire, or jumping to my long-term plan of adding a VFD should become a Christmas present for myself.

Setup: WM-56P with the original 2HP motor running off of a static phase converter on 220.

Problem: The overload is tripping left, right, and center...

Whenever I try to either run the lathe at a higher speed, say over 1200 RPM, I start to hear the SPC kick in and out rapidly until the overload trips. At first, I thought it was a belt tension problem. So, I went through all the belts to make sure they had plenty of slack, but I was stuck with the same problem. Anytime I'd try to get up to speed, the overload would trip. I checked with a clamp on ammeter and saw it drawing 9.5 amps on 220 volts with just the chuck spinning at 1000 RPM. I tried disconnecting the motor belt to see what the draw was with just the motor but I was still seeing ~6 amps. The nameplate of the motor says 6.8 amps at 208 volts. It may be worth noting that I see 240 volts on the line side of the contactor with the lathe off, but that quickly drops to 220 volts once running. I don't think that's an issue but that's beyond me.

This is where the extent of my knowledge leaves me. I don't know what step to take next to find the problem. I'm not sure if the motor is somehow worn out, if I should try searching for a bad wire, or jumping to my long-term plan of adding a VFD should become a Christmas present for myself.