- Joined

- Feb 1, 2015

- Messages

- 9,948

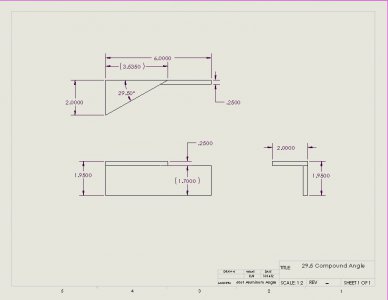

A 29.5 degree angle is most likely the most used angle set on the compound on a lathe. The Grizzly G0602 lathe has a difficult to read dial with 2-1/2 degree graduations. My solution was to make a gage that would provide easy and accurate setting of this important angle.

I made mine from a piece of 2" x 2" x 1/4" 6061 aluminum angle that I had in my scrap bin. I used my CNC to mill the piece but could have just as easily made it with a rotary table or by setting my milling vice at a 29.5 degree angle to the y axis. I roughed out the piece on a band saw and finished the milling with a 1/2" end mill. The entire project was an easy few hours

Because I was using some scrap for the piece, my version is not exactly to the drawing. Additionally, it works for the 0602 but the maker should check that the dimensions fit his or her particular lathe and make adjustments accordingly.

Enjoy!

I made mine from a piece of 2" x 2" x 1/4" 6061 aluminum angle that I had in my scrap bin. I used my CNC to mill the piece but could have just as easily made it with a rotary table or by setting my milling vice at a 29.5 degree angle to the y axis. I roughed out the piece on a band saw and finished the milling with a 1/2" end mill. The entire project was an easy few hours

Because I was using some scrap for the piece, my version is not exactly to the drawing. Additionally, it works for the 0602 but the maker should check that the dimensions fit his or her particular lathe and make adjustments accordingly.

Enjoy!