-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

220V Miller Machine, Dedicated for Spool Gun

- Thread starter erikmannie

- Start date

- Joined

- Sep 8, 2019

- Messages

- 4,392

...pay off that lathe!

I refinanced the lathe loan down to a 7.5% APR loan with payments of $150/week. After making that & all other payments, I have a surplus (discretionary funds approved by Mrs. Mannie) for further machine purchases. I am saving up for 2 more wire feed welders, a spool gun + a big mill, & that’s it for machines.

I have a few more years left of long overtime hours, but in about 5 years I will have to take a UPS job with just about zero overtime. This is my last chance to fully tool up before I permanently transition to a fixed income.

Last edited:

- Joined

- Apr 16, 2019

- Messages

- 746

We had a Miller mig welder at work with an optional spool gun , sorry I can’t remember which models . We kept it set for steel with the regular gun , the cart had two tanks on argon/co2 mix and the other argon . . The spool gun took a little time to get used to. I’m not a skilled welder but got by the repairs needed. Like any skill it takes time , what worked for using the spool gun and aluminum was to preheat the metal for me anyway. If I didn’t it would be too cold at the start and glob up then finish ok . We did use the spool gun on steel by switching bottles and wire , that came in handy when we had to climb on the trucks to get where the regular gun couldn’t reach . I’ve never aluminum welder anything thinner the 1/8” so cant comment on that . If my welder at home was able to use a spool gun I would get one .

- Joined

- Dec 24, 2020

- Messages

- 1,199

I'm sort of a welder geek and have owned literally dozens of Millermatic machines and most of the spool guns....Spoolmatic 1, Spoolmatic 3, Spoolmate 200, Spoolmatic 30A and they all work really nicely. They take some dialing in to get a feel for the wire speed and voltage combination, but it's not difficult. I think it took me about five minutes to get an acceptable bead the first time I ran one. The only real downside is that they only take the small spools of wire.I will probably be buying a wire feed welder in September that will be dedicated for a spool gun.

I prefer 220V Miller machines. I am considering a Millermatic 252 or Millermatic 255. I am just starting to look at it, but I think one choice for a gun is a 30A. I understand that I will want to use 100% Argon.

I have to save for many months, & I have never used a spool gun. The mechanic at work tried an Eastman machine + a HF spool gun, & he was unable to make any good welds. He gave up.

So does anybody have anything to say about spool guns?

Both the 252 and 255 will take a push/pull gun, which may be an option for you. The push-pull guns cost more, but for some things are better. The push/pull guns from Miller are a bit bulkier than the spool guns, but allow you to run a large diameter spool on the machine. You use U-shaped rollers in the machine's drive and there is a motor in the gun that pulls the wire. You adjust the push side on the machine to match up with the push-pull gun. The push-pull gun will be marked with a setting you put into the welder so the two are in sync...usually that's all it takes, but it can be tweaked if necessary. The other nice thing with the push-pull setup is that (at least on my 350P) when you adjust the wire speed at the gun end it shows in the wire speed display on the machine so you're not guessing what the wire speed is. On the Spoolmatic 30A it simply has a dial 1-10 that doesn't correlate directly to wire speed. I never ran a push-pull gun on my 252, but I would expect it and the 255 show wire speed on the machine as well. The push-pull guns do cost more than the spool guns, but nothing blue is cheap these days!

It seems like the folks doing heavier aluminum projects seem to go with the push-pull setup largely because of the big spool of wire. I've read about guys in the pacific northwest and Alaska who make aluminum boats and many of them say the push-pull setup is the only way to go. I've heard some of them will keep a spool gun handy for tighter spots, but that's probably overkill for most of us hobby welders.

What sort of projects are you planning? I think that would really dictate it more than anything else. If money is no object, just get a 350P Aluminum and be done with it...but it really is only for aluminum. The standard 350P with the push-pull gun is a close second and what I'm using now...really amazing machine.

- Joined

- Sep 8, 2019

- Messages

- 4,392

I'm sort of a welder geek and have owned literally dozens of Millermatic machines and most of the spool guns....Spoolmatic 1, Spoolmatic 3, Spoolmate 200, Spoolmatic 30A and they all work really nicely. They take some dialing in to get a feel for the wire speed and voltage combination, but it's not difficult. I think it took me about five minutes to get an acceptable bead the first time I ran one. The only real downside is that they only take the small spools of wire.

Both the 252 and 255 will take a push/pull gun, which may be an option for you. The push-pull guns cost more, but for some things are better. The push/pull guns from Miller are a bit bulkier than the spool guns, but allow you to run a large diameter spool on the machine. You use U-shaped rollers in the machine's drive and there is a motor in the gun that pulls the wire. You adjust the push side on the machine to match up with the push-pull gun. The push-pull gun will be marked with a setting you put into the welder so the two are in sync...usually that's all it takes, but it can be tweaked if necessary. The other nice thing with the push-pull setup is that (at least on my 350P) when you adjust the wire speed at the gun end it shows in the wire speed display on the machine so you're not guessing what the wire speed is. On the Spoolmatic 30A it simply has a dial 1-10 that doesn't correlate directly to wire speed. I never ran a push-pull gun on my 252, but I would expect it and the 255 show wire speed on the machine as well. The push-pull guns do cost more than the spool guns, but nothing blue is cheap these days!

It seems like the folks doing heavier aluminum projects seem to go with the push-pull setup largely because of the big spool of wire. I've read about guys in the pacific northwest and Alaska who make aluminum boats and many of them say the push-pull setup is the only way to go. I've heard some of them will keep a spool gun handy for tighter spots, but that's probably overkill for most of us hobby welders.

What sort of projects are you planning? I think that would really dictate it more than anything else. If money is no object, just get a 350P Aluminum and be done with it...but it really is only for aluminum. The standard 350P with the push-pull gun is a close second and what I'm using now...really amazing machine.

I have not heard of a 350P Aluminum. I am going to research that now.

If I don’t get a 350P Aluminum, it sounds like a push-pull gun is the way to go because this machine will only be for aluminum.

As for my projects, I like to become adept at various processes just for a fun exercise. As such, I prefer to weld all types of joints (e.g. butt, edge) in all positions, ideally on coupons.

When I am retired (10 years), I hope to do metal art or other ideas that I come up with. I do not enjoy doing paid work for others.

Edit: these are scary expensive!

Miller Millermatic 350P Aluminum MIG Welder (907474)

Miller has discontinued this Millermatic 350P package. The suggested replacement is the 907300 with push-pull gun or AlumaFeed systems. Optimized to weld aluminum, the Millermatic 350P Aluminum MIG Welder is perfect for fabrication, manufacturing, maintainance and repair. True Torque Feed Motor...

Second edit: now I see that the above does not include the gun. That is too expensive for me.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

Here are some Miller push-pull guns:

store.cyberweld.com

store.cyberweld.com

and

store.cyberweld.com

store.cyberweld.com

One could also add a suitcase to the conversation. I have not yet researched how a suitcase works.

In any case, I have to work & save for at least another 5 months, so I have plenty of time to think about it.

My 220V outlet only has a 40A breaker, so I have to keep that in mind. I can also do 3 phase 220V with a 40A circuit breaker.

Miller XR-Aluma Pro Lite Gun 300948

Miller XR™-Aluma Pro Lite Gun 300948 (Air-Cooled)The Miller XR™-Aluma Pro Lite gooseneck style MIG gun is a 175 amp push-pull wire feed gun that is lightweight and extremely economical. Miller's XR™-Aluma Pro Lite comes with 25 foot cables and hooks directly into your Millermatic® 252...

and

Miller XR-Aluma Pro A Gun - 25ft. 301569

Miller® XR-Aluma Pro™ A Gun - 25ft. 301569 (Air Cooled)The Miller® XR-Aluma Pro™ A is designed to deliver optimum results when feeding aluminum MIG welding wire and other soft alloy wires. The XR system offers the versatility to handle everything from light-gauge to heavy-plate applications.The...

One could also add a suitcase to the conversation. I have not yet researched how a suitcase works.

In any case, I have to work & save for at least another 5 months, so I have plenty of time to think about it.

My 220V outlet only has a 40A breaker, so I have to keep that in mind. I can also do 3 phase 220V with a 40A circuit breaker.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

Since this machine will be used exclusively for aluminum, I will try to save for a 3 phase 350P Aluminum. My only reservation is the 40A breaker in the shop.

I will call Miller Tuesday morning & ask what sized breaker they require for the 350P Aluminum.

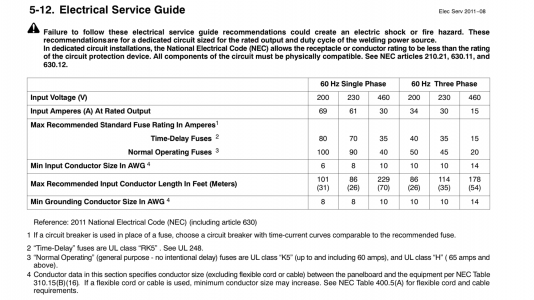

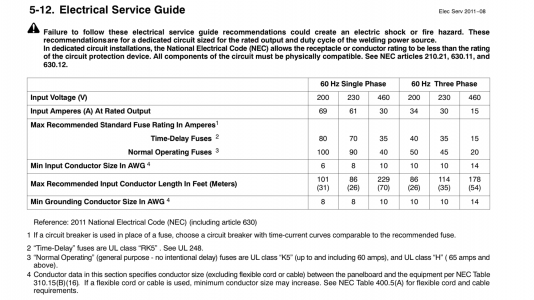

Edit: it looks like a 40A breaker would work for a 3 phase machine.

From:

Second edit: I have been running 220V welders at up to 210A for years, & I have never tripped the 40A breaker.

I will call Miller Tuesday morning & ask what sized breaker they require for the 350P Aluminum.

Edit: it looks like a 40A breaker would work for a 3 phase machine.

From:

Second edit: I have been running 220V welders at up to 210A for years, & I have never tripped the 40A breaker.

Last edited:

- Joined

- Sep 8, 2019

- Messages

- 4,392

So, like I said, the 350P costs too much. I am back to probably a Millermatic 255 with an appropriate push-pull gun.

I would still consider a Millermatic 252, but I wonder if Miller will phase these out in the next few years, even though they are clearly bombproof.

I would still consider a Millermatic 252, but I wonder if Miller will phase these out in the next few years, even though they are clearly bombproof.

That 350P aluminum set up is amazing but, hard to justify if it's not paying for itself. I put a flexible neck on my spool gun to access a tight project. It was a game changer, now it's easy to get comfortable welding in any position. It doesn't feel like I'm welding with a football anymore!