- Joined

- Mar 27, 2017

- Messages

- 213

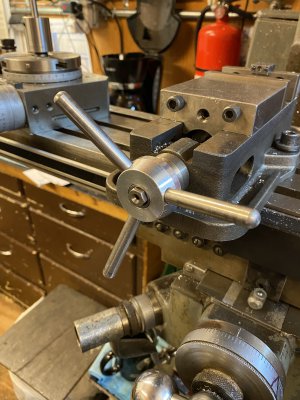

Found the “handle” for my 3” kurt vise was not so user friendly. Easy to over torque and slightly awkward. Decided to copy the concept of a spinner type of handle. Made one similar to the ones advertised for the larger vises except it needed to be much smaller. Here are some pictures of what I know many of you have also done. This tool limits the over torquing and speeds up jaw movement on the vise. I have found it to be very handy.

I simply pressed a 7/16” socket into the 7075 bar stock after putting a straight knurl on the socket. Has held up well ! The handles are 5/16” 1018 with 1/4-20 threads. I put a 1/8” deep 5/16” counter bore for a flat registry in the body. So far this seems to give the handles added regidity and works very well under the torque necessary for a 3” vise.

I simply pressed a 7/16” socket into the 7075 bar stock after putting a straight knurl on the socket. Has held up well ! The handles are 5/16” 1018 with 1/4-20 threads. I put a 1/8” deep 5/16” counter bore for a flat registry in the body. So far this seems to give the handles added regidity and works very well under the torque necessary for a 3” vise.

Attachments

-

837C36C5-2D32-48D4-9460-1B321615FA74.jpeg690.1 KB · Views: 22

837C36C5-2D32-48D4-9460-1B321615FA74.jpeg690.1 KB · Views: 22 -

847B7A52-01B7-441C-8302-54D021CD00AB.jpeg1.6 MB · Views: 23

847B7A52-01B7-441C-8302-54D021CD00AB.jpeg1.6 MB · Views: 23 -

6F34279A-1D07-4CA2-A7BB-E8E1E6071A94.jpeg1.5 MB · Views: 24

6F34279A-1D07-4CA2-A7BB-E8E1E6071A94.jpeg1.5 MB · Views: 24 -

015E8475-FB06-4FDA-9F25-9CF7A4E8663F.jpeg1.7 MB · Views: 23

015E8475-FB06-4FDA-9F25-9CF7A4E8663F.jpeg1.7 MB · Views: 23 -

AD37C465-15A0-41FE-880C-471829EA12D2.jpeg817.2 KB · Views: 24

AD37C465-15A0-41FE-880C-471829EA12D2.jpeg817.2 KB · Views: 24

Anyways , it's a bag sealer prototype .

Anyways , it's a bag sealer prototype .