POTD was making a sign for our new chicken coup. My wife drew up the coup in Unigraphics, we did the cuts and assembly in the shop before breaking down the walls for final assembly behind our garage.

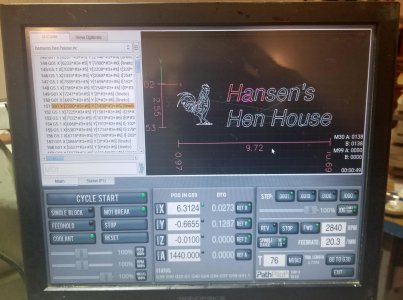

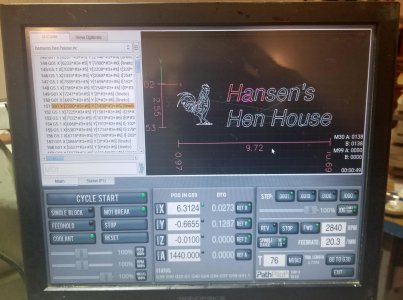

Found a DXF file on the web of a rooster, included some text to personalize the sign. Not that anyone looking at the building can figure out what it is, but nice to get out in the shop and take advantage of the 53 F first day of winter in Michigan.

Tormach has an on-line version of PathPilot which I used to size and put the routine together. It’s a nice feature though most CNC’ers on the forum probably do their CAD/CAM inside and take the final result to their shops for cutting anyhow. First use of on-line PathPilot for me; no surprises when running the routine in the shop.

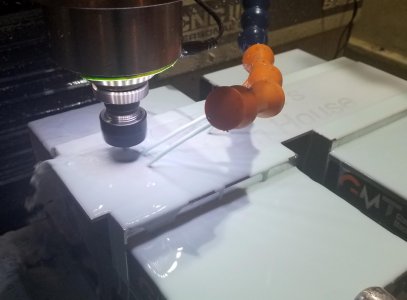

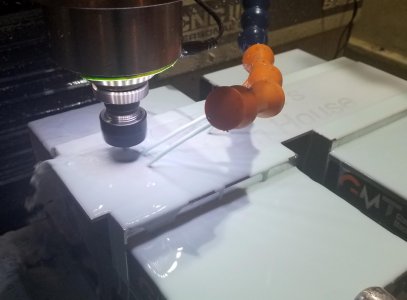

I use TrimSol for coolant which is an opaque blue. I’ve never had a problem with it starting to stink with bacteria like other coolants, but it is hard to see the progress of a routine. Will go to a clear coolant when the TrimSol gets too filthy. I don’t know the name of the coolant Tormach uses on their YouTube videos, but it’s clear which makes it easy to see how the cutting is going. The sign was cut with a 15 deg. carbide engraving tool at a final depth of 0.015". D/A sanded after engraving, painted the engraving with a black paint pen and final sanded before cutting to length.

Thanks for looking.

Bruce

Did the pre-work for the routine sitting at our house computer using Tormach's on-line PathPilot. Really nice to have a cup of coffee with Baileys while watching the news and developing the routine. Dumped the file to a flash drive and headed to the shop.

Hard to tell what's going on when the stock is covered with coolant . . .

Took about 12 minutes to run the routine. Used a carbide 15 deg. engraver at a final depth of 0.015" (in two passes).

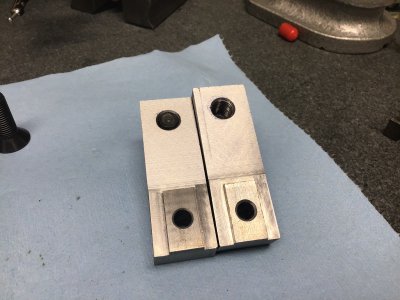

Leaning toward the carbide engravers over a diamond drag. The engravers remove stock and leave a nice furrow while the diamond drag doesn't really cut, more plows through material. I sanded the aluminum plate after engraving and filled in the engraving with a paint pen. D/A sanded the plaque, cut to length and drilled/countersunk a couple of screw holes.

Hansen's Hen House plaque in place on the coup, just in case anyone stopping over can't figure out what the building is . . .