Several months ago I found some undimensioned sketches on the net that showed how to convert a coax indicator to a 3D taster. Seemed like an interesting project as I had a cheap import coax indicator that I bought several years ago that didn't get used much. After gathering the necessary materials, i.e. a 6mm rod end, #9 carbide drill, 6mm - 1.0 carbide tap, and a ruby tipped stylus I went to work.

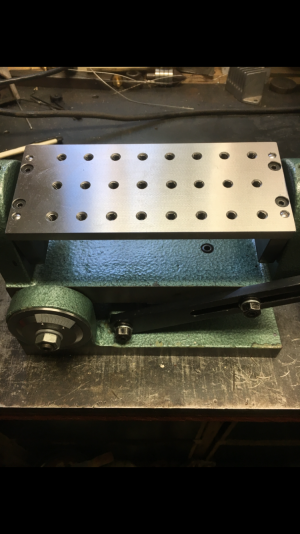

Here's the finished product.

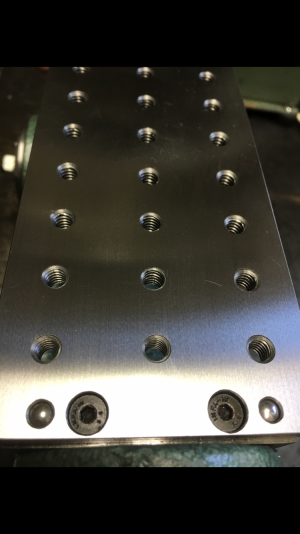

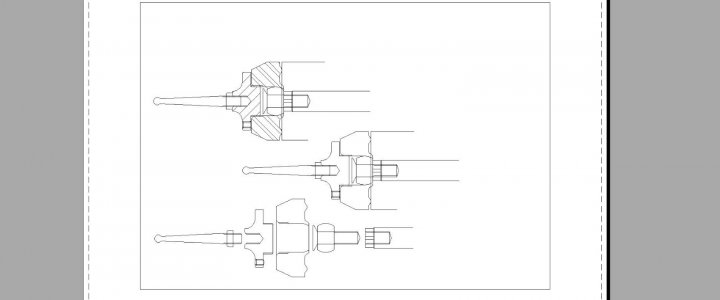

This is a layout of the individual parts before assembly. There is a spacer that goes between the plunger shaft and ball that is not shown.

After assembly I mounted the taster in a collet and adjusted the stylus runout until I got it within .0005" TIR. Using a 123 block clamped in my vise and a edge finder as my reference tool I located my X and Y zero points and set my mill DRO's to zero. Using my new 3D taster I probed the 123 block X and Y axis and set the taster dial to zero. I took the taster in and out of the spindle several times and probed the 123 block and it repeated to less than .001" each time. I haven't tried setting the Z axis height yet but that is the next step.

It's important to mention that the dial markings are not 1 to 1. In other words if you locate an edge and need to offset from that edge use the hand wheel dials or DRO to get your offset.

I'm pleased with the results at about 1/3 the cost of a Haimer.

Here's the finished product.

This is a layout of the individual parts before assembly. There is a spacer that goes between the plunger shaft and ball that is not shown.

After assembly I mounted the taster in a collet and adjusted the stylus runout until I got it within .0005" TIR. Using a 123 block clamped in my vise and a edge finder as my reference tool I located my X and Y zero points and set my mill DRO's to zero. Using my new 3D taster I probed the 123 block X and Y axis and set the taster dial to zero. I took the taster in and out of the spindle several times and probed the 123 block and it repeated to less than .001" each time. I haven't tried setting the Z axis height yet but that is the next step.

It's important to mention that the dial markings are not 1 to 1. In other words if you locate an edge and need to offset from that edge use the hand wheel dials or DRO to get your offset.

I'm pleased with the results at about 1/3 the cost of a Haimer.