These are projects I completed over several days.

The first was to sort my washer collection. Over 30 years I had sorted the extraneous washers I picked up along the way by eyeball. The final straw came when I couldn't get the one washer drawer to close. It was time to sort them so I made a gage with progressively larger diameters corresponding to the inch sizes of washers. Here's the washer sorter. I need to sort the small washer drawer for the stuff of size 10 and smaller. I'll need to make another washer gage for that.

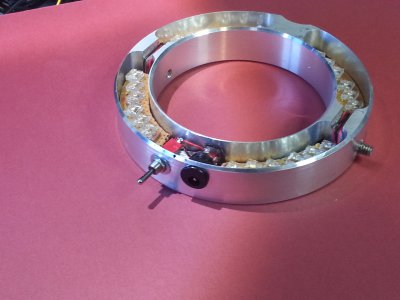

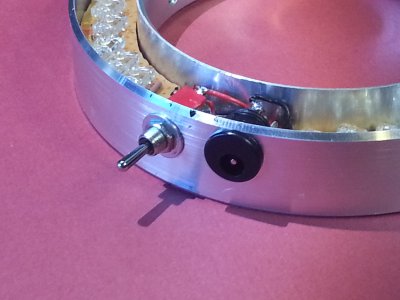

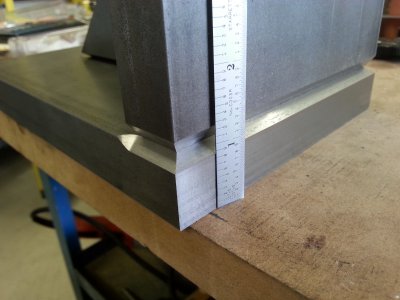

The next project was to repair one of two Superior Electric variacs / variable transformers I picked up at a yard sale. The smaller one had been dropped. Its wiring was also old and becoming stiff. It required some sheet metal work to straighten out the dents. While I was at it, I rewired the internals giving it slightly longer internal wires to make it easier to take off and put on the junction box. I also updated the receptacle to 3 prongs. The receptacle is held in place by a snap ring. I'd never seen one like that before. When I was at the local electronics shop to pick up a top to the fuse holder and an 8A fuse I mentioned the receptacle. The owner looked at it and said - that's a standard Amptrol receptacle, I think I have some. He indeed did have them, although the groove for the snap ring was in the wrong place, so I had to change the groove width with my lathe. The variac's top was lightly spot welded to the ventilated sides and those welds were broken for the repair. I'll epoxy the top back on when I'm satisfied I can't think of any more sheet metal improvements I want to make. The larger of the two variacs was mostly just dirty. It had a 3 prong plug and a 2 prong outlet receptacle. I updated the output with a grounded 3 prong receptacle on that too. It will handle both 115 and 240 volts. In playing with both of them, I never realized that variacs will also boost voltage. The larger of the two can take 110 volt input and output from 0 to around 300 volts. While I was rewiring the variac, I got disgusted by the disorganized box of wire I have and labeled many of the various wires with their AWG.

I picked up at a Weller soldering station at a flea market this summer for $5. It came with two handles but one didn't heat. The variac project stimulated me to mess with that. I thought it was the heating element, but it turned out that there was a broken wire in the cord. I first shopped for a new cord - the cheapest price was around $36 plus shipping. That gave me incentive to find the break in the wire. I knew which of the five wires wasn't conducting. I put my ohmmeter at the two ends of the affected wire and started wiggling it over short distances until I found the area that would make it temporarily conduct. The break occurred at the strain relief as the cord entered the handle. I opened the outer sheath of the cord, and dissected out the offending 22 AWG wire with the break. I soldered that back together again using the other handle. Now I have two working handles.

Oh. and at a yard sale a couple of weeks ago I picked up a drill index / case with a few bits in it. I needed to populate the holes, so it was time to sort all the old small drill bits I'd accumulated over the years. Although I must have had 75 to 100 extraneous drill bits, I still have some open holes in the index. When it's fully populated, I'll sharpen all of them. I'd be interested in swapping my extras for bits I need. Anybody want to swap some of your extras for mine?

Pix to follow if / when the attach image function works. Update - I managed to add the photos using the add photos icon on the toolbar, but the manage attachments function still isn't working. When I click on the manage attachments box, the popup window opens, but there's nothing in the box. I checked my security settings and added this site to specifically allow popups, but still no go.

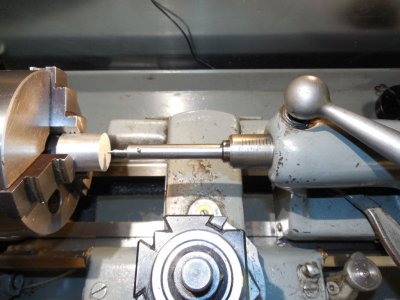

. The angle i ran the tool at to clear the live center made the chip miss the chip breaker on the insert. Im going to make the guy his sample pc but he needs 200 pcs. Afraid me gonna have to call my friend w cnc's to do that many or Ill be turning cranks for a year of sundays and wear out my little lathe!!

. The angle i ran the tool at to clear the live center made the chip miss the chip breaker on the insert. Im going to make the guy his sample pc but he needs 200 pcs. Afraid me gonna have to call my friend w cnc's to do that many or Ill be turning cranks for a year of sundays and wear out my little lathe!!

. The angle i ran the tool at to clear the live center made the chip miss the chip breaker on the insert. Im going to make the guy his sample pc but he needs 200 pcs. Afraid me gonna have to call my friend w cnc's to do that many or Ill be turning cranks for a year of sundays and wear out my little lathe!!