- Joined

- Feb 21, 2013

- Messages

- 34

My 1236T lathe arrived in mid December (ordered in June) in great shape. After opening the crate it was determined that the panel to connect the two stands was not in the crate, a quick call to Charlie had it being shipped. Yea for GREAT customer service.

It took till last week to arrange time for a friend to bring his engine hoist over to get it on the stands. Had time to start cleaning on the pallet. got power cord wired.

BTW- I had ordered a tri-power BX25 belt in advance based on other posts regarding poor quality of supplied belt. However, the BX25 I received was substantially bigger than the supplied belt and was too big to tighten on the pulleys. Will order a BX24 (unless someone here has better info). Running with original for now.

Love this machine!

- Tapped feet holes to 1/2-13. Existing is 12 tpi I think so it is good fit for industrial machine leveling feet.

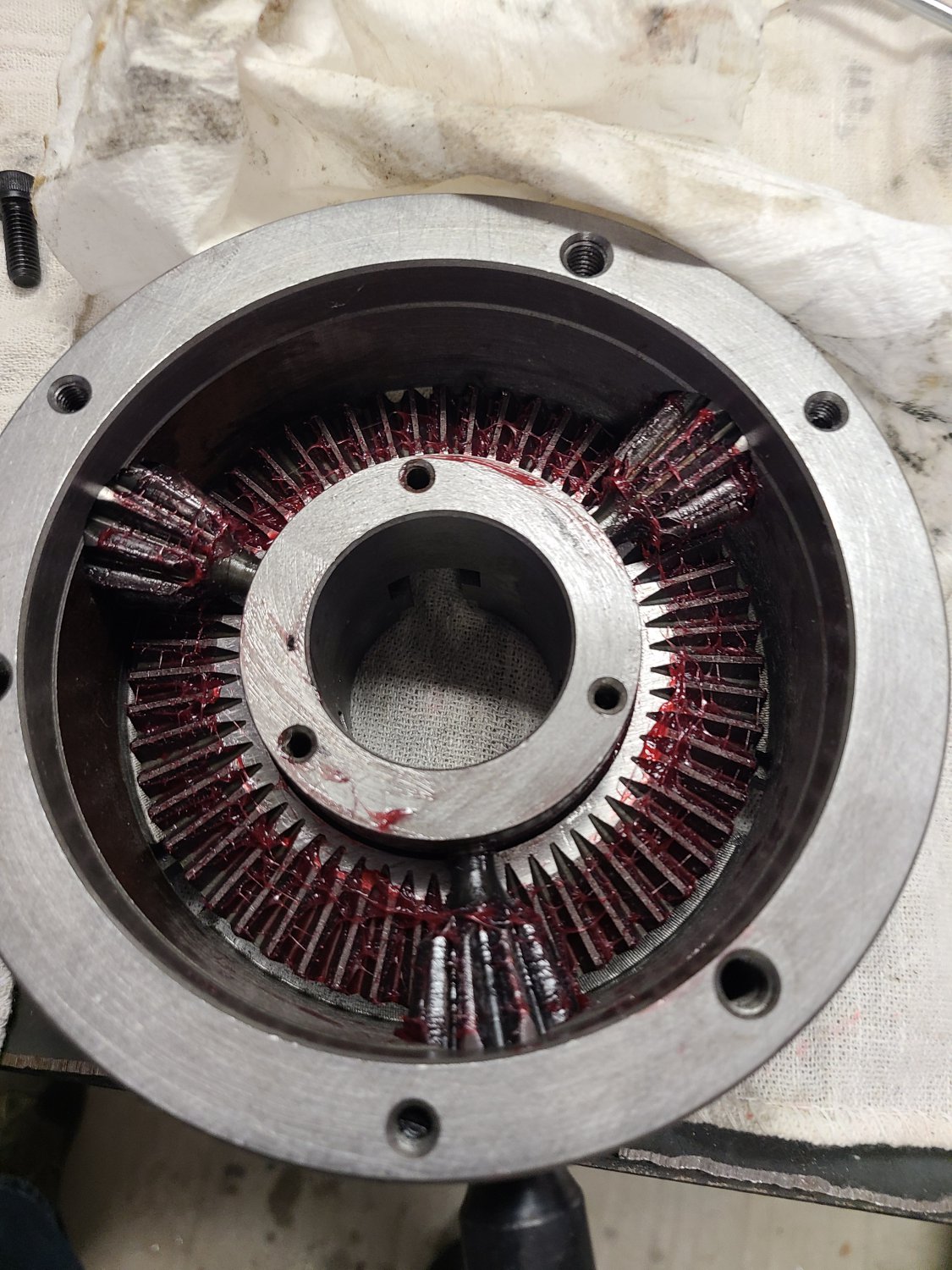

- Disassembled the supplied chuck. It is rough. The rear gear teeth are cast and not cut. Kind of "crunchy" when turning. Photo shows after I sanded teeth and greased it. Also ran sanding block thru the scroll groove and greased. Maybe helped a little. Don't have definitive run out on it yet. First glance it may be in 4-6 thou out.

- Top of compound must have been surface ground after the t-nut on 4-way was installed. Fooled me for a bit. It appeared to not be a t-nut. Could not see the surface until close look. Just loosen the set screws in the top of the t-nut and tap with a wood block and it will drive out.

- Made my T-nut for QCTP.

- Turned a piece of aluminum-bronze I had.

- Turn new handle for the rotation switch/handle.

Made first chips. Made new knob for the on/off rotation switch lever.

ONWARD and UPWARD. Another Happy Camper!

(P.S. - Please ignore the surrounding mess. Organization in progress. )

)

JT

It took till last week to arrange time for a friend to bring his engine hoist over to get it on the stands. Had time to start cleaning on the pallet. got power cord wired.

BTW- I had ordered a tri-power BX25 belt in advance based on other posts regarding poor quality of supplied belt. However, the BX25 I received was substantially bigger than the supplied belt and was too big to tighten on the pulleys. Will order a BX24 (unless someone here has better info). Running with original for now.

Love this machine!

- Tapped feet holes to 1/2-13. Existing is 12 tpi I think so it is good fit for industrial machine leveling feet.

- Disassembled the supplied chuck. It is rough. The rear gear teeth are cast and not cut. Kind of "crunchy" when turning. Photo shows after I sanded teeth and greased it. Also ran sanding block thru the scroll groove and greased. Maybe helped a little. Don't have definitive run out on it yet. First glance it may be in 4-6 thou out.

- Top of compound must have been surface ground after the t-nut on 4-way was installed. Fooled me for a bit. It appeared to not be a t-nut. Could not see the surface until close look. Just loosen the set screws in the top of the t-nut and tap with a wood block and it will drive out.

- Made my T-nut for QCTP.

- Turned a piece of aluminum-bronze I had.

- Turn new handle for the rotation switch/handle.

Made first chips. Made new knob for the on/off rotation switch lever.

ONWARD and UPWARD. Another Happy Camper!

(P.S. - Please ignore the surrounding mess. Organization in progress.

JT