Here's a picture of the whole lathe for ya. Tried to do a little turning on a tranny shaft but it was a bit too hard for my dull bits and lack of technique. Today I try to sharpen some of the HSS bits I have, did a LOT of reading on it last night. One thing I read was a little surprising to me and something I used to do but thought I was being a cob job mechanic. Someone said don't bother using the tool holders unless you HAVE TO..just put the bit itself in the toolpost. I have done that, stacking 3/8 bits to get it to a good height, and had OK results...Should I keep doing it that way or make new and sharp bits for my 1/4 inch holders?

I already figured out not to let the compound get too extended...If I keep it back over its base it doesn't seem any where near as flexible. I also think I need to work on adjusting the gibs for the saddle and another of todays jobs is leveling the lathe and getting it firmly bolted down to its stand in ALL the bolt holes. :madebooboo:

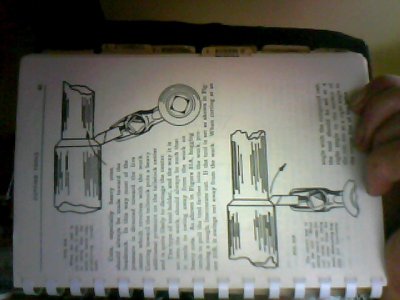

Interesting smiley assortment we have here!! Anyhow, the PIC:

I already figured out not to let the compound get too extended...If I keep it back over its base it doesn't seem any where near as flexible. I also think I need to work on adjusting the gibs for the saddle and another of todays jobs is leveling the lathe and getting it firmly bolted down to its stand in ALL the bolt holes. :madebooboo:

Interesting smiley assortment we have here!! Anyhow, the PIC: