- Joined

- Sep 28, 2022

- Messages

- 177

I posted a reply in another thread and decided in order to reply more fully that I would start a new thread.

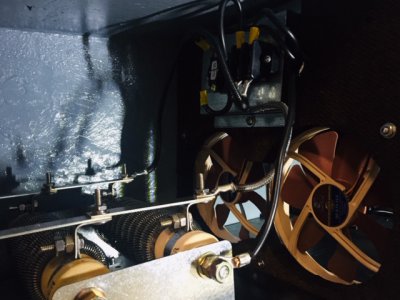

In the earlier thread I shared some pictures of my Monarch 10EE VFD conversion. It’s a 1968 modular machine with a maximum speed of 4,000 rpm. My conversion retained all of the original controls including the ELSR, and I also retained the original back gear. I chose to use a Black Max 7.5 hp with encoder in a closed loop system. The drive I used was a Nidec M701 with an interface module. And it also has a 20-ohm 1,500 watt brake.

I decided to retain the 4,000 rpm and to change pulleys to 1:1. This increase in drive rpm not only had ramifications for motor rpm and hertz but there were also some mechanical drive considerations that have to be addressed and even modified.

I had a chance to compare the performance side-by-side with a 1952 10EE motor generator that I also did some restoration on. The drive in it was in excellent shape and original. I could also talk about this if there is interest.

The mechanical condition of this machine was really good. It was a one owner machine out of a lab and the ways were in really good condition. There was about .0145 clearance between the flat tailstock way and the underside of the saddle. It did need spindle bearings because the front flange bearing had an issue on one point on the outer race.

I did dismantle the entire machine, replaced quite a few bearings overall, cleaned and painted the machine, and of course went through the oil system.

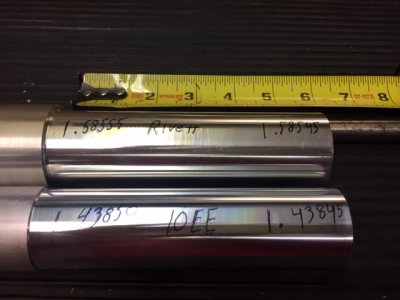

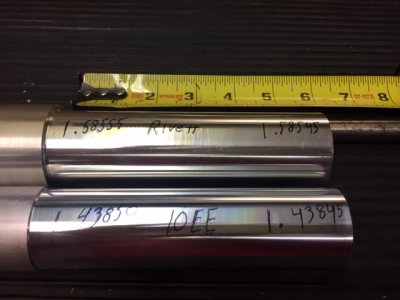

As far as the accuracy of the machine, I’ve include a picture of a test bar it cut after new spindle bearings. The picture also includes a 1020s Rivett test bar beside the Monarch’s because I replaced spindle bearings and restored that machine also.

Regarding the drive conversion, it is probably helpful to state that my goal was to achieve a performance equal to the original drive. So I chose to keep the back gear and go with a closed loop tenv motor. I know that many believe that a sensorless vector drive is adequate for this application. And I believe in theory that is correct. But after talking with some techs and engineers, I came to the conclusion that application is sometimes different than theory.

I have four other VFD drives in the shop (Hitachi, Lenze and Baldor) which are sensorless vector. The difference is smoothness, quietness, and responsiveness of the drive especially at low RPMs down to zero. In fact, at zero I can grab a 6” chuck, start to turn it, the drive will grab it back from me, return it to its position, and I am unable to hold it. The drive reacts quicker to changing torque requirements than do the sensorless vectors I have. Also, the drive and motor combination seem to produce little to no heat regardless of rpm or ambient conditions.

One other performance advantage was the installation an interface module which allowed a tech a DP Brown, the supplier and consultant on this drive system, to connect directly with the drive to tune parameters and view the results via an oscilloscope in real time. I was able to watch this via a connected laptop. Performance was enhanced from this step.

A test I did that probably everyone could relate to was to chuck up a piece of 1018 cold roll steel, drill a small pilot hole and drill the 1” hole at around 130 rpm in direct drive and it had no problem with this. When using a 6" steel set-true chuck, performance when acceleration and deceleration are turned up are approximately 0 to 4,000 rpm back to 0 in approximately three seconds. And it will do this time after time.

I discovered that when setting up deceleration rates all I really needed when using the ELSR for threading at about 400 or 500 rpm was for the carriage to stop almost instantly. In other words – no coasting. This gives you a very repeatable result with little need for much of a relief cut. Acceleration rates I adjusted to a more comfortable rate.

In the next post I can talk a little more about the actual gear box modifications and materials used in the electrical conversions plus the reasons for my choices.

Below are the pictures of the restored machine and of the completed drive conversion.

In the earlier thread I shared some pictures of my Monarch 10EE VFD conversion. It’s a 1968 modular machine with a maximum speed of 4,000 rpm. My conversion retained all of the original controls including the ELSR, and I also retained the original back gear. I chose to use a Black Max 7.5 hp with encoder in a closed loop system. The drive I used was a Nidec M701 with an interface module. And it also has a 20-ohm 1,500 watt brake.

I decided to retain the 4,000 rpm and to change pulleys to 1:1. This increase in drive rpm not only had ramifications for motor rpm and hertz but there were also some mechanical drive considerations that have to be addressed and even modified.

I had a chance to compare the performance side-by-side with a 1952 10EE motor generator that I also did some restoration on. The drive in it was in excellent shape and original. I could also talk about this if there is interest.

The mechanical condition of this machine was really good. It was a one owner machine out of a lab and the ways were in really good condition. There was about .0145 clearance between the flat tailstock way and the underside of the saddle. It did need spindle bearings because the front flange bearing had an issue on one point on the outer race.

I did dismantle the entire machine, replaced quite a few bearings overall, cleaned and painted the machine, and of course went through the oil system.

As far as the accuracy of the machine, I’ve include a picture of a test bar it cut after new spindle bearings. The picture also includes a 1020s Rivett test bar beside the Monarch’s because I replaced spindle bearings and restored that machine also.

Regarding the drive conversion, it is probably helpful to state that my goal was to achieve a performance equal to the original drive. So I chose to keep the back gear and go with a closed loop tenv motor. I know that many believe that a sensorless vector drive is adequate for this application. And I believe in theory that is correct. But after talking with some techs and engineers, I came to the conclusion that application is sometimes different than theory.

I have four other VFD drives in the shop (Hitachi, Lenze and Baldor) which are sensorless vector. The difference is smoothness, quietness, and responsiveness of the drive especially at low RPMs down to zero. In fact, at zero I can grab a 6” chuck, start to turn it, the drive will grab it back from me, return it to its position, and I am unable to hold it. The drive reacts quicker to changing torque requirements than do the sensorless vectors I have. Also, the drive and motor combination seem to produce little to no heat regardless of rpm or ambient conditions.

One other performance advantage was the installation an interface module which allowed a tech a DP Brown, the supplier and consultant on this drive system, to connect directly with the drive to tune parameters and view the results via an oscilloscope in real time. I was able to watch this via a connected laptop. Performance was enhanced from this step.

A test I did that probably everyone could relate to was to chuck up a piece of 1018 cold roll steel, drill a small pilot hole and drill the 1” hole at around 130 rpm in direct drive and it had no problem with this. When using a 6" steel set-true chuck, performance when acceleration and deceleration are turned up are approximately 0 to 4,000 rpm back to 0 in approximately three seconds. And it will do this time after time.

I discovered that when setting up deceleration rates all I really needed when using the ELSR for threading at about 400 or 500 rpm was for the carriage to stop almost instantly. In other words – no coasting. This gives you a very repeatable result with little need for much of a relief cut. Acceleration rates I adjusted to a more comfortable rate.

In the next post I can talk a little more about the actual gear box modifications and materials used in the electrical conversions plus the reasons for my choices.

Below are the pictures of the restored machine and of the completed drive conversion.

Attachments

Last edited: