1) the carriage now moves with some friction, until it gets towards the right side of the bed and then binds. I measured the gap closer to the headstock. Is it possible the bed is worn enough end to end to cause this. I could adjust the gib so as it has more clearance on the one end.

Yes, At the far right end where the tailstock usually sits I found that mine would get a bit tight, I adjusted to allow about 0.002" on the apron gib and the other gib on the carriage I adjusted so that things slid but there was a slight increase in the force as I neared the far right side of the lathe. Typically with the tailstock there you can't really work the carriage much so I thought that would be A-OK. The wear I suspect is more from dragging the carriage lock and having the rear saddle gib too tight as they really only keep the carriage from lifting.

New sight glass: https://www.ebay.com/itm/M-1652-BIJUR-B5944-5-8-OIL-LEVEL-WINDOW-TREE-MACHINE-PART-/303599864677 says may not ship to Canada but that is what you are looking for - Bijur B5944 (that is the updated part number)

2) the cross slide feed now only works if I pull the Feed Selection Plunger and hold it in place. Guess I have to pull the apron back off again.

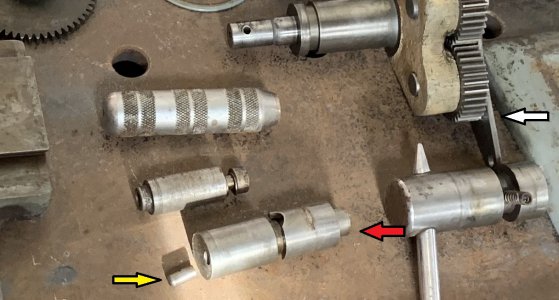

That is strange, Did you take it all apart? The feed selector just moves the one gear. There is a detent at the back of the shaft that locks the selector in position. It is indicated on the picture with the red arrow pointing to the set screw. Under that should be a spring and ball. The blue arrow is the feed gear for the cross feed and the pink arrow is the drive for the carriage assembly. The middle position you can use the threading handle. The set screw adjusts the tension of the spring on the ball to lock in the feed selector. I played with the adjustment to get it feeling like a solid click into position.

The chewed up power feed gear - I have the gear cutters to make this part and the part laid out in autoCAD. Just need to get some material and that all important "time to make one" or perhaps two.....LOL