I have something similar in both fine & rough. I'm no expert, just a hobbyist, but I think roughing EM's are often overlooked for smaller duty machines like we use. Roughers were probably targeted for big boy production machines. But the way I look at it, its just easier on our smaller ones even if we don't care about time or output. They cut with so much less drama, less vibration, higher removal, less heat.. I have a 1/2" fine rougher & 1/2" spiral finisher in 2 different R8 adapters. My go-to method for many parts is rough to within 0.010", then swap in the finisher (thus preserving DRO settings). The EM diameter tolerances seems to work out very close. So what I'm saying is there is value in have 2 EM's of the same diameter whatever you choose.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Apr 17, 2015

- Messages

- 323

The more flutes the lighter the chip load per flute, the better for roughing. Life of these depends on quality and use. Better tools with better coatings last longer. Not pushing tooling to is capacity helps them last. Both of these need to be balanced by your budget. (tooling budget and time profit budget)

- Joined

- Jan 23, 2017

- Messages

- 228

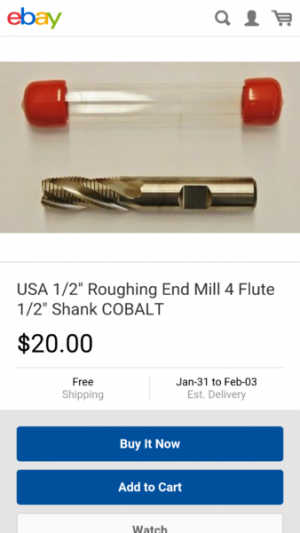

I'm wondering what would be the difference in choosing a 3 vs 4 flute? ? ?

A 33% increase in feed rate, or a 25% decrease in chip load depending on perspective.

I use these: http://www.cgstool.com/products/r240-5000eo-1.html refurbished 1/2" carbide $8

Sometimes they are on ebay for $5-6

Sometimes they are on ebay for $5-6

I'm wondering what would be the difference in choosing a 3 vs 4 flute? ? ?

There is also an advantage to 3 flutes in some applications because flutes do not oppose each other. For instance, when cutting a slot and 180 deg. of the end mill is in contact with the work. Means less vibration, better finish I think.

U

umahunter

Forum Guest

Register Today

U

umahunter

Forum Guest

Register Today

- Joined

- Nov 27, 2012

- Messages

- 7,912

I can't seem to post links for some reason? ??

I logged in under your account & tried, worked fine. First link above was just cut & paste. Second link was using the url tool in the message editor.

Which method did you try? Can you try another browser?

U

umahunter

Forum Guest

Register Today

this HTML class. Value is http://www.ebay.com/ that's what I get when I copy link and paste

U

umahunter

Forum Guest

Register Today

Don't know why it's probably my phone but that's what I do everywhere else and it works fine