- Joined

- Jul 1, 2012

- Messages

- 1,356

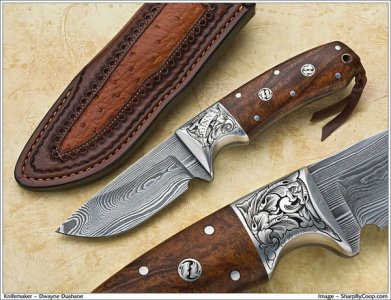

I made my first knife in 8th grade shop class out of a file, with a brass guard and a mesquite handle. Gave it to my big brother & several months later found it rolling around in the back of his pickup. It took him a lot of smooth talking before I made him another one. Still making them & loving it, sell them all over the world. I'm hoping to get my grandkids into making them.

Dwayne

Dwayne what a perfect lead in to see your work.

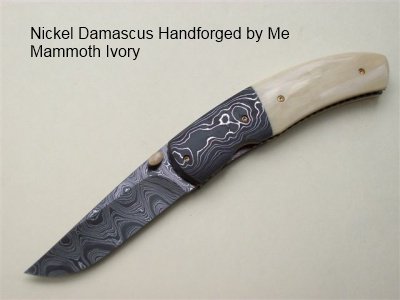

Do you have a few pictures to share? I can't wait to make a knife again. I have been dreaming about after I retire to make some knifes and blacksmith tools. I will be moving down to Missouri and build a new shop and will make things and try to sell them at the local flee market, just to have fun making and meeting people. DMS isn't it just so cool how the steel is hand forged. Next time you guys smelt something please show us how you do it. Rich

PS: Dwayne did you ever find a Milling machine?