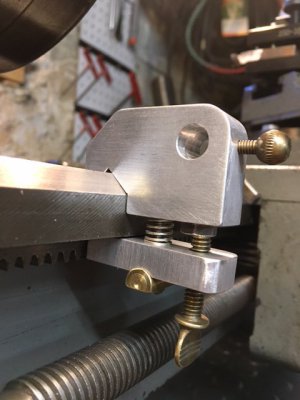

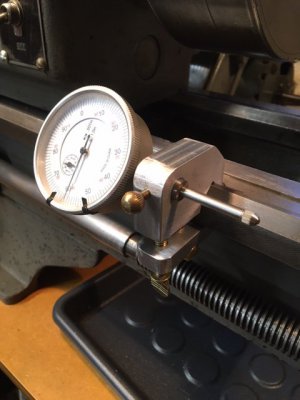

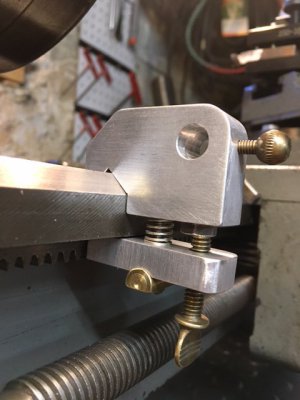

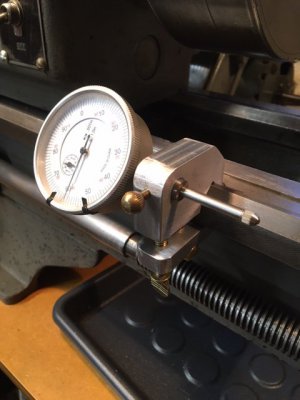

In September i picked up a Montgomery Ward (Logan) 10x24 lathe. It was a huge step up from my Atlas made Craftsman 6x18, and i've been really enjoying it. Recently i made some optical center punches and was missing having an indicator stop for the carriage movement. So, off to the scrap bin(s). Some aluminum stock, some brass bits, a small spring, and a small stainless steel hex bolt did the job.

I know different people prefer different methods, but i've come to really appreciate using an indicator stop. I can also replace the indicator with a hard stop by center drilling and tapping a stub of 3/8" rod, then inserting a small machine screw (such as a #8x32) with a lock nut, but i might make a dedicated adjustable hard stop out of steel for durability.

Next up modifying an anonymous center rest to fit the lathe.

I know different people prefer different methods, but i've come to really appreciate using an indicator stop. I can also replace the indicator with a hard stop by center drilling and tapping a stub of 3/8" rod, then inserting a small machine screw (such as a #8x32) with a lock nut, but i might make a dedicated adjustable hard stop out of steel for durability.

Next up modifying an anonymous center rest to fit the lathe.