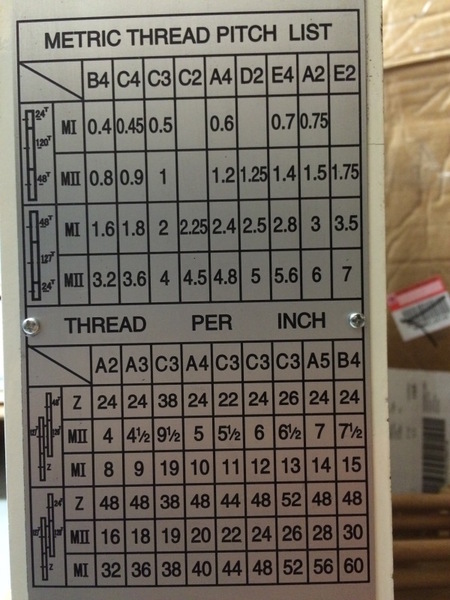

Ok here is my table (metric machine) :

and

Right now the machine is in configuration where top = 24, middle = 120, bottom = 48 and both top and bottom mesh on the 120 side.

I just can't see how I'm supposed to switch to the second metric configuration without flipping over the middle gear.

To me the drawing is clear that both mesh on the 127T side of the middle gear, with the 48 up and the 24 down.

Look at the configuration to cut imperial threads, in that particular case yes it is very clear that both sides of the middle gear are used at the same time.

Do I make sense ?

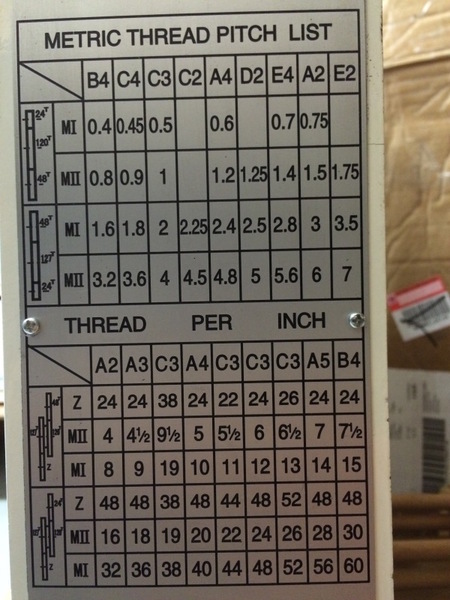

and

Right now the machine is in configuration where top = 24, middle = 120, bottom = 48 and both top and bottom mesh on the 120 side.

I just can't see how I'm supposed to switch to the second metric configuration without flipping over the middle gear.

To me the drawing is clear that both mesh on the 127T side of the middle gear, with the 48 up and the 24 down.

Look at the configuration to cut imperial threads, in that particular case yes it is very clear that both sides of the middle gear are used at the same time.

Do I make sense ?