- Joined

- Jul 20, 2016

- Messages

- 43

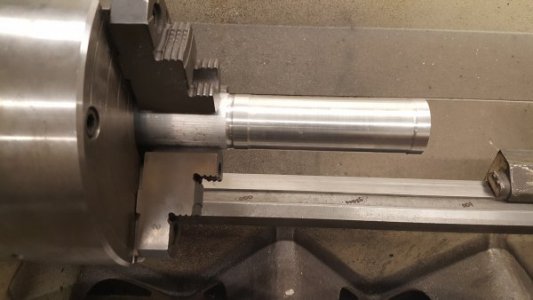

I have an old 13" South Bend lathe that has a ridge on the top of the ways is that going to be a bad for the accuracy of the lathe I know the lathe is WW2 vintage.I've also read and seen on youtube that you can still do good work on an old worn out lathes but others say you can't could I get some advice on this please thanks.