- Joined

- Apr 23, 2018

- Messages

- 6,573

Loctite sleeve retainer "green" is specified for woodruff keys and will handle a .004 gap. Perfect!

Yes - this indeed is apparently what has happened before in the life of the key from the SB-9A. There are two punch marks, and that "stops the wobble". The other key (SB-9C) just wobbles awayCenterpunch the sides of the key in a few places, tap it in...good to go.

My thanks for that! As much as 0.004" does surprise me.Loctite sleeve retainer "green" is specified for woodruff keys and will handle a .004 gap. Perfect!

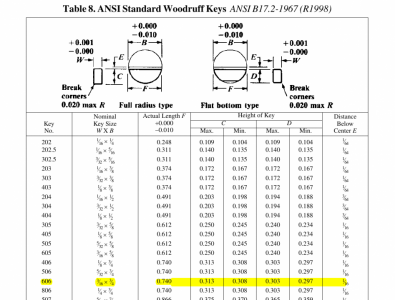

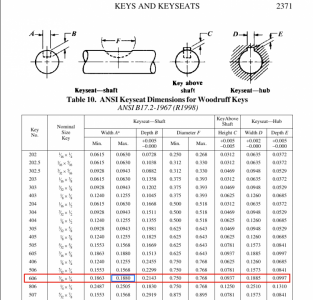

I am definitely with John and yourself on this one. Given I have them all apart, this is the opportunity to put them together right!If the key doesn't clock something precisely, could you cut a new accurate keyway 90 or 180 from the worn one? A Woodruff key should be an interference fit, with a depth and height above the key that falls within tolerances.

I agree with John; the key should fit well or it will just wear again.

I used the Loctite sleeve retainer for sloppy fitting crank bearings when rebuilding racing kart engines (picture a Briggs & Stratton 6.5hp built up to 21hp).Loctite sleeve retainer "green" is specified for woodruff keys and will handle a .004 gap. Perfect!