I wasn't that lucky in my shop. I didn't have a metal lathe. I did have a big external thread chaser. You selected the thread pitch and then dial it out until it fit. Sort of like a pipe wrench. Used it for axles and hydraulic cylinders.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wood turning on a metal lathe using the carriage / tool post vs free hand?

- Thread starter Aaron_W

- Start date

- Joined

- Jun 7, 2013

- Messages

- 10,111

The thread chasers that I wrote about were rectangular, kind of like a file without teeth, and then teeth machined on one end with front clearance and a tang on the other end for a file handle, they are used in a lathe on a hand rest to cut threads or dress up damaged threads,I wasn't that lucky in my shop. I didn't have a metal lathe. I did have a big external thread chaser. You selected the thread pitch and then dial it out until it fit. Sort of like a pipe wrench. Used it for axles and hydraulic cylinders.

- Joined

- Jun 7, 2013

- Messages

- 10,111

Not easy to find, I had pretty much a full set in imperial, had to leave them when I sold my business, but can go back and borrow them when I have need. Seemed like most of them were made by Pratt & Whitney.I got them in Metric & Imperial. Have used them for years. Can't live in the repair world without them. I thought you meant a 60 degree hand held graver.

Out of curiosity, how fast will your Atlas turn? It seems like a lot of the wood lathes go up to 3500 RPM or so, but metal lathes are limited to about 2000 rpm. Did you run into any problems with this?I turned more wood on my Atlas 12" lathe than metal.

I don't know how crucial this is. I'm guessing the higher speed is more important for small diameter parts, but I don't know what size it would start to be important.

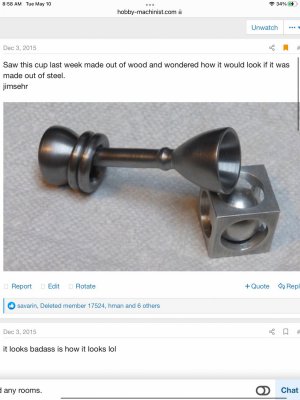

I've used a 7 x 10 mini metal lathe for wood turning (pens) for a number of years. I started with a home made Tee rest for hand turning. I also built and added a pattern tracing mod to the lathe so I could cut curved surfaces using the tool post, carriage and power feed. I do make a tool bar that holds wood turning carbide inserts that works really well. Inserts designed for aluminum cutting also work good for wood and plastics, they have a sharper polished cutting edge.

I also added an electric motor driven variable speed (slow) drive to make finishing cuts. I can go straight to 400 grit sand paper after turning.

Danny

I also added an electric motor driven variable speed (slow) drive to make finishing cuts. I can go straight to 400 grit sand paper after turning.

Danny