- Joined

- Mar 9, 2018

- Messages

- 465

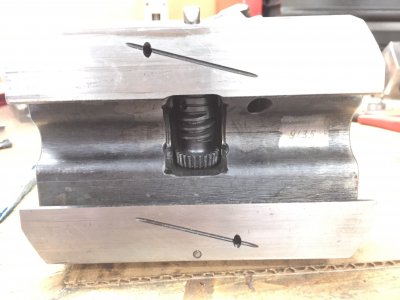

I recently acquired a Wohlhaupter UPA 5* that I plan to sell off for a few extra bucks to put back into the shop. These things are combination boring / facing heads. Meaning: it can work like a regular boring head. But if you grab onto the collar while it's spinning, it'll automatically feed the slide out (or in), allowing you to face with it. The UPA 5 can actually turn tapers too if you use it with the auto-downfeed of your machine. The outfeed is stepwise-adjustable in twelve increments between 0.0008 and 0.0096 in/rev on the radius.

More out of curiosity than anything else, I cracked'er open to see what makes it tick, and cleaned it all up in the process. A few hours in a hot ultrasonic bath did the trick. By my count, there are at least 142 individual parts making this up. Mine is missing a few of the clamp screws and stuff like that, but none of the bits that make it work.

Figured you folks may be interested in some of the photos. I'll take a few more as I re-assemble it to show a bit better how the mechanism works. There is a little bit of info out there on the smaller UPA 3s, but very little on the UPA 5. So maybe this'll help someone out of a jam some day.

The first photo with everything assembled isn't mine; I just grabbed it from the internet. The pictures of the guts are mine.

*I also acquired a Wohlhaupter UPA 3, which I plan to keep. Disassembling / cleaning that one is on my to-do list as well. Maybe I'll post some similar photos if there's interest.

More out of curiosity than anything else, I cracked'er open to see what makes it tick, and cleaned it all up in the process. A few hours in a hot ultrasonic bath did the trick. By my count, there are at least 142 individual parts making this up. Mine is missing a few of the clamp screws and stuff like that, but none of the bits that make it work.

Figured you folks may be interested in some of the photos. I'll take a few more as I re-assemble it to show a bit better how the mechanism works. There is a little bit of info out there on the smaller UPA 3s, but very little on the UPA 5. So maybe this'll help someone out of a jam some day.

The first photo with everything assembled isn't mine; I just grabbed it from the internet. The pictures of the guts are mine.

*I also acquired a Wohlhaupter UPA 3, which I plan to keep. Disassembling / cleaning that one is on my to-do list as well. Maybe I'll post some similar photos if there's interest.

I kept my smaller Wohlhaupter and my larger Narex and sold all my other plain boring heads .

I kept my smaller Wohlhaupter and my larger Narex and sold all my other plain boring heads .