- Joined

- Jun 15, 2017

- Messages

- 525

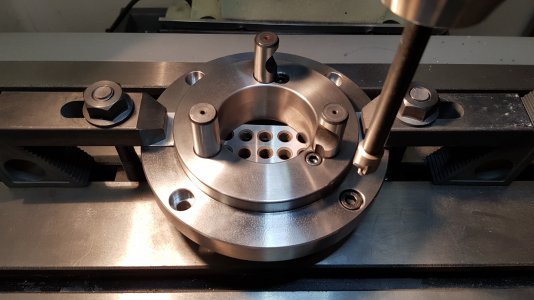

I'm putting my shop back together after a long time away from my tools. Yesterday I decided to adjust my 3-jaw chuck, even though I had done this years ago. I was surprised to see it was way out of adjustment.

The first time I adjusted it, I put a piece of tape on the lathe spindle so I could remember how the chuck was clocked with regard to it. Of course, I forgot what the tape corresponded to on the chuck, so when I reinstalled the chuck, it may or may not have been lined up the same way.

I'm wondering if other people put witness marks on chucks so they'll be aligned as well as possible after being taken off and reinstalled.

The first time I adjusted it, I put a piece of tape on the lathe spindle so I could remember how the chuck was clocked with regard to it. Of course, I forgot what the tape corresponded to on the chuck, so when I reinstalled the chuck, it may or may not have been lined up the same way.

I'm wondering if other people put witness marks on chucks so they'll be aligned as well as possible after being taken off and reinstalled.