Hello, folks.

I'm hoping some of the electrical specialists here can help me out. I'm fairly clueless on motor wiring, so this is basically the last thing between me and getting this Logan/MW 10x24 up and running.

A little background: I picked up this Logan/Montgomery Wards lathe (I believe it's the 84TLC-2130) from a smaller machine shop last year. It had clearly been stored for a long time, but was fairly complete and largely original. I completely disassembled it, cleaned everything, assembled it, lubed everything that needed it, and leveled the lathe. It's back together now, but I've saved the wiring (my nemesis) for last.

It came with the original, 1/2hp dual voltage 1ph Wards motor, capacitor start. Here's the best photo I could get of the faded motor plate:

There are six leads coming out of the motor, all red wires with original labels. As best as I could tell and assuming no labels fell off, this is how they're labeled: 2, C 5, J 6, 7, 8, and E.

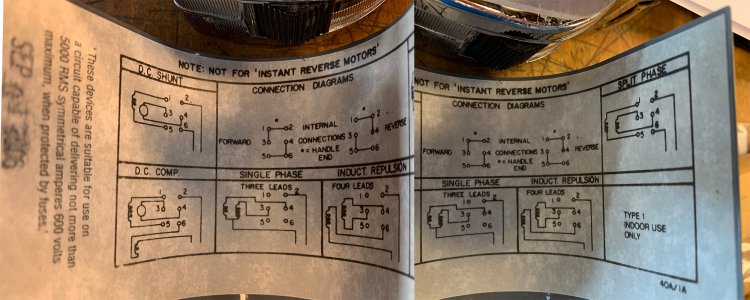

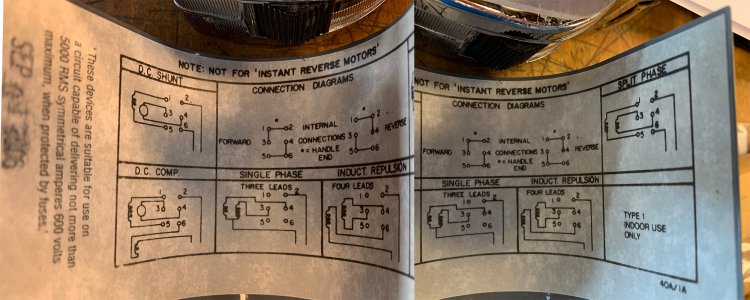

It was missing the front half of the original switch, so I bought a new Dayton 2X440A reversing drum switch to use instead. Here's the diagram on the inside of the switch cover:

I don't believe the original Logan wiring instructions are a lot of help since this is not an original switch, but it is here.

http://lathe.com/wiring_diagrams.htm

(I think I have the "1105" motor on the right side of the page).

The bottom line is that I'd like to wire it 110V, but I'm lost on how to interpret these diagrams. Any help would be fantastic.

Thank you!

Zayd

I'm hoping some of the electrical specialists here can help me out. I'm fairly clueless on motor wiring, so this is basically the last thing between me and getting this Logan/MW 10x24 up and running.

A little background: I picked up this Logan/Montgomery Wards lathe (I believe it's the 84TLC-2130) from a smaller machine shop last year. It had clearly been stored for a long time, but was fairly complete and largely original. I completely disassembled it, cleaned everything, assembled it, lubed everything that needed it, and leveled the lathe. It's back together now, but I've saved the wiring (my nemesis) for last.

It came with the original, 1/2hp dual voltage 1ph Wards motor, capacitor start. Here's the best photo I could get of the faded motor plate:

There are six leads coming out of the motor, all red wires with original labels. As best as I could tell and assuming no labels fell off, this is how they're labeled: 2, C 5, J 6, 7, 8, and E.

It was missing the front half of the original switch, so I bought a new Dayton 2X440A reversing drum switch to use instead. Here's the diagram on the inside of the switch cover:

I don't believe the original Logan wiring instructions are a lot of help since this is not an original switch, but it is here.

http://lathe.com/wiring_diagrams.htm

(I think I have the "1105" motor on the right side of the page).

The bottom line is that I'd like to wire it 110V, but I'm lost on how to interpret these diagrams. Any help would be fantastic.

Thank you!

Zayd

Last edited by a moderator: