- Joined

- Jan 22, 2022

- Messages

- 128

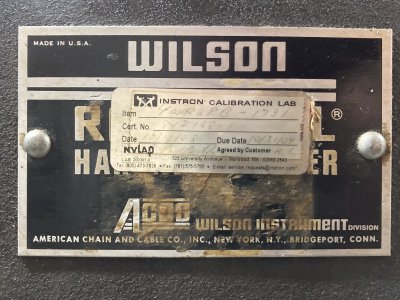

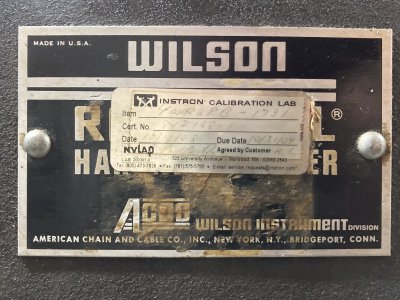

Hey guys. I picked up a Wilson hardness tester today for $300. Model 4 OUR a RB. That model number is a mouthful.

Everything looks complete as far as I can tell. In very good condition, has all anvils, a diamond and ball penetrator and multiple test blocks. BUT I CAN’T GET IT TO WORK!

I watched a few YouTube videos and I swear I’m operating it the way they do. But the needle doesn’t seem to move after flipping the lever.

My best guess is something is out of adjustment. The lever that holds the weights isn’t making contact with what connects to the hand lever after I set the pre load. Can anyone tell me what I’m missing here?? Or maybe I’m doing something wrong??

Thank you

EDIT: I did add oil to the oil dash pot and adjusted the speed. That did not fix my problem.

View attachment trim.6A9EBD4E-644D-4B8C-B24F-69A99BCFC18F.MOV

Everything looks complete as far as I can tell. In very good condition, has all anvils, a diamond and ball penetrator and multiple test blocks. BUT I CAN’T GET IT TO WORK!

I watched a few YouTube videos and I swear I’m operating it the way they do. But the needle doesn’t seem to move after flipping the lever.

My best guess is something is out of adjustment. The lever that holds the weights isn’t making contact with what connects to the hand lever after I set the pre load. Can anyone tell me what I’m missing here?? Or maybe I’m doing something wrong??

Thank you

EDIT: I did add oil to the oil dash pot and adjusted the speed. That did not fix my problem.

View attachment trim.6A9EBD4E-644D-4B8C-B24F-69A99BCFC18F.MOV

Last edited: