-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why Can't I get my DTI to Repeat

- Thread starter ddickey

- Start date

- Joined

- Aug 15, 2013

- Messages

- 2,113

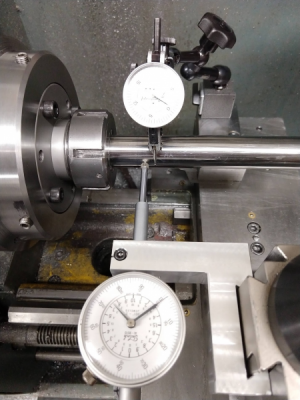

To eliminate indicator error, have you tried setting up a DTI and a DI at the same time to see if they both follow the same pattern?Mike it does repeat but every third rotation.

Noga ordered.

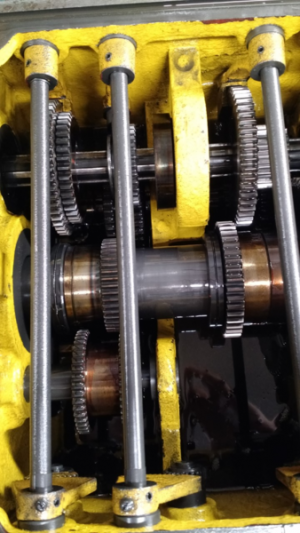

The every third rotation thing, if repeatable, would seem to indicate (pardon the pun) that the problem is somewhere in the rotating mass, not the indicator(s). And, I would think that if the pattern repeats every 3 rotations of the chuck, it might have something to do with a gear or belt drive binding? Maybe a gear or pulley that’s in a 1:3 ratio with the spindle?

If none of that, I’m out of spitballs and will loan you my “Exorcism for Dummies” book.

Tom

OK... just for fun, try one more thing. Using the setup pictured, and without moving anything else, try withdrawing the indicator point and gently letting it return to contact. Should come back to the same reading. If it does (as I expect it will), I'm out of ideas. If it doesn't, you're on the way toward understanding the problem.

-or-

Try gently moving the extended stem up and down. If it moves, the irregularity in readings may be due to the tip "falling off" the peak of the test rod as it makes contact above, on and below center. I will try.

I'll try that also.Maybe try tightening the spindle preload nut until it takes a bit of force to turn and see if the problem persists? (Don't run it under power like that)

Sent from my LYA-L29 using Tapatalk

Interesting, I have not tried setting up two. I will try that also. I have a few errands to run today before going back to work tomorrow. Thanks all for the great suggestions.To eliminate indicator error, have you tried setting up a DTI and a DI at the same time to see if they both follow the same pattern?

The every third rotation thing, if repeatable, would seem to indicate (pardon the pun) that the problem is somewhere in the rotating mass, not the indicator(s). And, I would think that if the pattern repeats every 3 rotations of the chuck, it might have something to do with a gear or belt drive binding? Maybe a gear or pulley that’s in a 1:3 ratio with the spindle?

If none of that, I’m out of spitballs and will loan you my “Exorcism for Dummies” book.

Tom

Watching this thread picking up all ideals.Been watching YouTube’s on tuning up a lathe cause I am having alignment issues.Just wondering if the headstock is out which mine is,discovered that when boring for bushing

- Joined

- Dec 2, 2012

- Messages

- 1,723

To eliminate indicator error, have you tried setting up a DTI and a DI at the same time to see if they both follow the same pattern?

The every third rotation thing, if repeatable, would seem to indicate (pardon the pun) that the problem is somewhere in the rotating mass, not the indicator(s). And, I would think that if the pattern repeats every 3 rotations of the chuck, it might have something to do with a gear or belt drive binding? Maybe a gear or pulley that’s in a 1:3 ratio with the spindle?

If none of that, I’m out of spitballs and will loan you my “Exorcism for Dummies” book.

Tom

Ahh

It kinda sounds like theirs some issue with the bearings possibly being a little warn or out of round or maybe a dent in the race, or as higgie says some binding in the drive, although I think you mentioned you had tried it with the lath in neutral.

How far away from the headstock are you measuring the run out ? as you say theirs only 1/2 thou on the spindle itself.

Also what kind of lath is it ? is their any provision for bearing adjustment apart from pre load?

Stu

- Joined

- Feb 1, 2015

- Messages

- 9,605

May or may not be your problem but when bearings are going, the readings will repeat every other rotation. This is because the bearings rotate around the spindle half as fast as the spindle rotates.

- Joined

- Dec 2, 2012

- Messages

- 1,723

Other than preload not that I know of.

2000 Acra-Turn 13x40.

I suppose about 3-4" from the spindle face.

If it's easy to pop the spindle out I would maybe have a visual look at the bearings and races to check for damage but if it's as much of a faf as my leblond which is also a gear head then I would definitely check everything else first.

Stu