- Joined

- Oct 15, 2013

- Messages

- 298

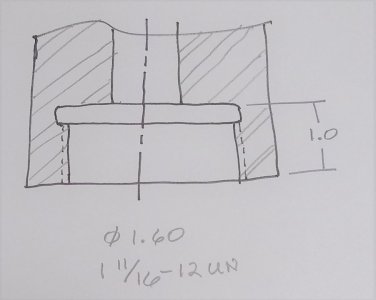

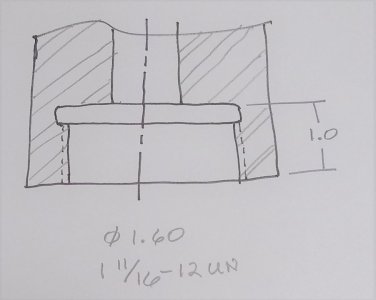

So I was repairing a part and needed to make a flat bottom bore with a thread relief so I could cut an internal thread. (quickie sketch attached) I looked through the limited odd assortment of holders and boring bars that I do have and nothing was a good fit for the feature. I did get a good part made, but not a pretty one..

So, using HSS tooling on an Atlas 10E with quick change tool post, what would a proper tool be to cut an internal thread relief, and to face off the flat bottom of the bore? What would it look like?

Thanks!

So, using HSS tooling on an Atlas 10E with quick change tool post, what would a proper tool be to cut an internal thread relief, and to face off the flat bottom of the bore? What would it look like?

Thanks!