- Joined

- Oct 29, 2012

- Messages

- 1,329

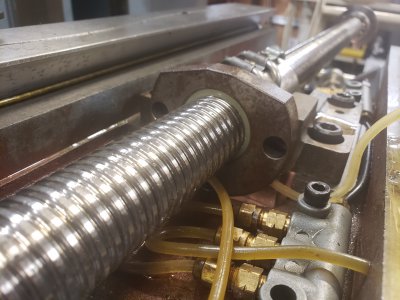

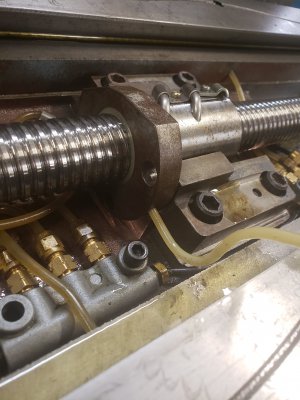

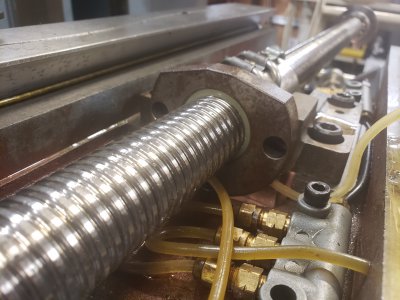

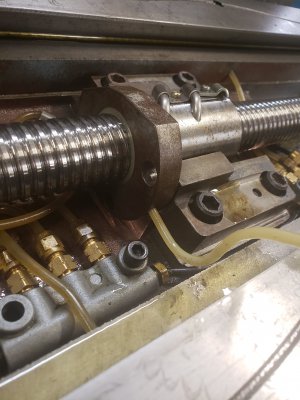

I started this restoration of a 1988 Lagunmatic CNC mill a couple of years ago and now I'm picking up where I left off. I took lots of pictures and tagged everything with notes, because I know myself and I'm prone to extended hiatus(es?) in the middle of projects. So here's how it looked coming apart (this is the x-axis ballscrew/ballnut) :

Ya see that little oiler tube just floating in mid-air? That was dribbling oil down onto the x-axis ballscrew. Right next to the wiper portion of the nut, which I suspect did its job and wiped all the oil off the ballscrew before it could get into the ballnut where it was needed.

Probably not coincidentally, the balls inside were thoroughly thrashed. I had 7 thou of slop in the x-axis and when I took the balls out they were inconsistent sizes and out of round. (I re-balled it, hopefully it's not too far gone)

So I'm thinking that dribbling oil onto a ballscrew outside the ballnut is not an effective means of lubrication. Am I correct? I would be happy to be wrong and just put it back the way it was; that would be easy.

But there's this nagging little hole on the bottom quadrant of the ballnut that looks suspiciously like the image results that I get when I google "ballnut oil hole." However, those images all show fittings. I have no fittings. The hole is not threaded and I'm not even 100% certain that it goes all the way through. Oil tube conveniently fits right in there. With some RTV or something, it might not even leak. Buuuttt.... since it's on the bottom I'm not sure the oil would get up to where it needs to be. I would expect the hole to be in the top of it were for oil.

So do I cram my tube in that hole or let it dribble on the ballscrew?

Ya see that little oiler tube just floating in mid-air? That was dribbling oil down onto the x-axis ballscrew. Right next to the wiper portion of the nut, which I suspect did its job and wiped all the oil off the ballscrew before it could get into the ballnut where it was needed.

Probably not coincidentally, the balls inside were thoroughly thrashed. I had 7 thou of slop in the x-axis and when I took the balls out they were inconsistent sizes and out of round. (I re-balled it, hopefully it's not too far gone)

So I'm thinking that dribbling oil onto a ballscrew outside the ballnut is not an effective means of lubrication. Am I correct? I would be happy to be wrong and just put it back the way it was; that would be easy.

But there's this nagging little hole on the bottom quadrant of the ballnut that looks suspiciously like the image results that I get when I google "ballnut oil hole." However, those images all show fittings. I have no fittings. The hole is not threaded and I'm not even 100% certain that it goes all the way through. Oil tube conveniently fits right in there. With some RTV or something, it might not even leak. Buuuttt.... since it's on the bottom I'm not sure the oil would get up to where it needs to be. I would expect the hole to be in the top of it were for oil.

So do I cram my tube in that hole or let it dribble on the ballscrew?