- Joined

- Jul 30, 2011

- Messages

- 47

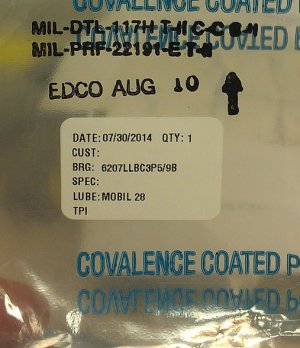

Thanks for bearing advice. A couple days ago I took thenrie's advice and ordered from Alpine Bearing. I'll post their part number if it works. Basically it's an ABEC 5, Grease pack, Rubber seals, 35mm X 72mm X 17mm. ($28)

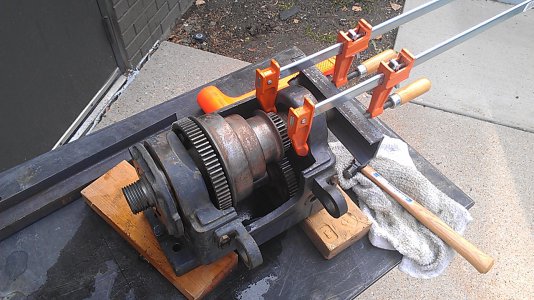

Now I've put it back except for the rear bearing, and after it's all in, I get a gap on the front shield or ring or whatever it's called. Yeesh, how did I do that? (Maybe pounding it out from the other side?) And has anyone seen that before? It's not going in further without a fight. I'm back to stone knives and bearskins!

Now I've put it back except for the rear bearing, and after it's all in, I get a gap on the front shield or ring or whatever it's called. Yeesh, how did I do that? (Maybe pounding it out from the other side?) And has anyone seen that before? It's not going in further without a fight. I'm back to stone knives and bearskins!